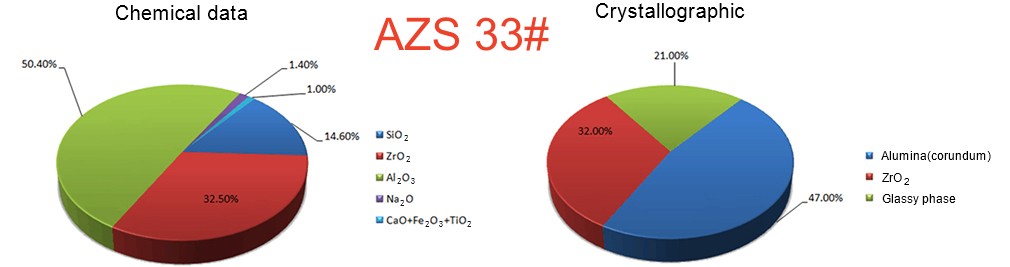

ZrO2≥32.5

Al2O3≥50.00

Bulk density: ≥3.45-3.75

Application:

Fused Cast AZS 33# Blocks are widely used in the various parts of the glass furnace.

AZS 33# PT blocks can be used in breast wall, front wall, burner wall, port area and etc.

AZS 33#ZWS and AZS 33# WS blocks can be used as Tank sidewall blocks and Tank bottom paving.

Introduction of fused cast AZS 33# blocks:

Fused cast AZS 33# blocks made from a combination of alumina (Al2O3), zirconia (ZrO2), and silica (SiO2) are the basic quality grade of fused cast refractory blocks used in the glass furnace. AZS 33# blocks denotes the percentage of ZrO2≥32.5%. Different Companies may have different indication code. For example, SEPRO uses ER 1681 for AZS 33#, and REFEL uses 1532 for AZS 33#. With the lowest zirconium oxide content in the standard fused cast AZS product range, AZS 33# Refractory block is the essential refractory material for glass furnaces. Its chemical and physical properties make it be used in various areas of the glass furnace.

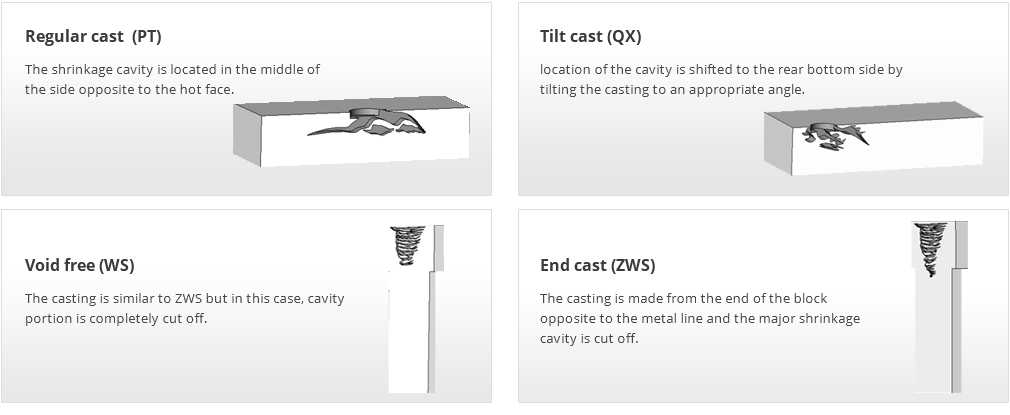

Classification of fused cast AZS33# blocks:

Fused cast AZS 33# Refractory blocks are normally classified into three quality grades:

AZS 33#PT (normal casting), AZS 33#ZWS (End Cut Casting) and AZS 33#WS (Void Free)

|

Type |

Casting method |

Description |

Bulk density Kg/dm³ |

Application |

|

PT |

Regular cast |

The shrinkage cavity is located in the middle of the side opposite to the hot face. |

≥3.45-3.5 |

•superstructures |

|

ZWS |

End cast |

The casting is made from the end of the block opposite to the metal line and the major shrinkage cavity is cut off. |

≥3.65-3.7 |

•sidewalls |

|

WS |

Void free |

The casting is similar to ZWS but in this case, cavity portion is completely cut off. |

≥3.7-3.75 |

•sidewalls |

Casting types of fused cast AZS33# blocks:

Fuse Cast AZS 33# Refractory Block Chemical and Physical Datasheet:

|

Item |

AZS33 |

|

|

Chemical |

Al2O3 |

≥47%-50% |

|

ZrO2 |

≥32.50 |

|

|

SiO2 |

≤15.00 |

|

|

Na2O |

≤1.50 |

|

|

Fe2O3+TiO2 +CaO |

≤0.25 |

|

|

Apparent Porosity % |

≤1.2 |

|

|

Cold Crushing Strength Mpa |

≥200 |

|

|

Exudation Temperature of Glass Phase |

≥1400 |

|

|

Bubble Separation Ratio(1300℃×10h) |

≤1.2 |

|

|

Anti-corrosion rate of glass liquid |

≤1.5 |

|

|

|

PT(RN RC N) |

≥3.45-3.5 |

|

ZWS(RR EVF EC ENC) |

≥3.65-3.7 |

|

|

WS( RT VF EPIC FVP DCL) |

≥3.7-3.75 |

|

More pictures of AZS33# Blocks :

As a professional fused cast AZS refractory blocks manufacturer, Henan SNR refractory Co.,ltd will always keep improving to provide the high quality products and service. If any question or demand of fused cast AZS blocks, please feel free to contact us.