--Strong corrosion resistance

--Stable phase structure

--Good thermal stability

--Low pollution

Advantages of choosing fused cast AZS blocks

1. Strong corrosion resistance

Fused cast AZS#41 blocks contain 40%-42% ZrO₂. The presence of ZrO₂ makes the block body have good resistance to glass liquid corrosion. In the throat of the glass furnace, the glass liquid scours and corrodes the sidewall for a long time, and the high content of ZrO₂ can effectively resist the corrosion of alkali metal ions in the glass liquid, maintain good stability, reduce the degree of corrosion, and thus extend the service life of the throat.

2. Stable phase structure

Its petrographic structure is composed of the eutectic of corundum and zirconite and the glass phase. This stable phase structure further improves the corrosion resistance. The eutectic of corundum phase and zirconite phase can maintain good stability in the corrosive environment of glass liquid, and the glass phase is filled between the crystals, which enhances the overall density of the block and prevents the penetration of glass liquid.

In the high temperature environment of the throat (generally around 1400℃-1600℃), fused cast AZS #41 blocks maintain good physical and chemical properties. It is resistant to deformation and damage when subjected to hydrostatic pressure and flow washout of glass liquids.

3. High glass phase seepage temperature

Fused cast AZS #41 blocks have an extremely high glass phase seepage temperature. This means that the glass phase in the block is less likely to seep out into the glass solution at high temperatures in the glass furnace, thus avoiding contamination of the glass solution due to glass phase seepage. This is conducive to improving the quality and purity of glass products.

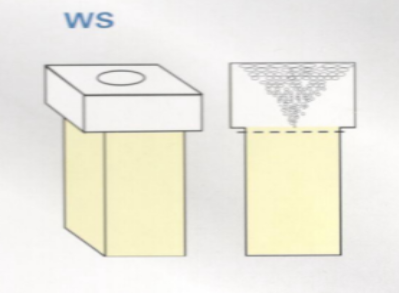

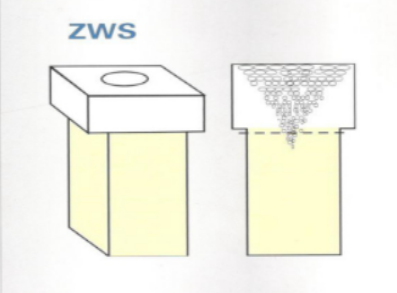

Casting method:

|

Type |

Casting method |

Description |

Bulk density Kg/dm³ |

|

|

|

The casting is made from the end of the block opposite to the metal line and the major shrinkage cavity is cut off. |

|

|

|

|

The casting is similar to ZWS but in this case, cavity portion is completely cut off. |

|

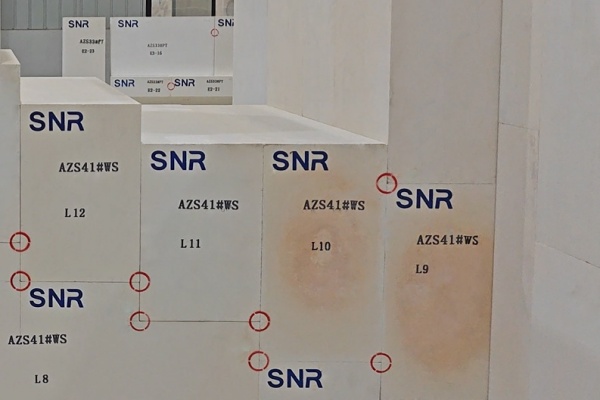

Casting types of fused cast AZS41# blocks:

Related Products

As a professional fused cast AZS refractory blocks manufacturer, Henan SNR refractory Co.,ltd will always keep improving to provide the high quality products and service. If any question or demand of fused cast AZS41# blocks, please feel free to contact us.