Fused cast AZS block erosion not only affects the stability of the glass furnace, it can also affect the quality and productivity of the glass product. Understanding the mechanism of fused cast AZS block erosion can help glass furnace designers and operators to identify and optimise glass furnace construction, operating parameters and maintenance strategies to improve the overall performance and stability of the glass furnace. By understanding the causes of erosion, targeted measures can be taken to slow down the rate of fused cast AZS block erosion, thereby extending its service life, reducing the frequency of replacement and repair, and lowering production costs.

1. Erosion of fused cast AZS blocks in glass furnaces

2. Erosion Characteristics of Fused Cast AZS Block in Electric Glass Furnace

3. Extension of service life of fused cast AZS blocks in electric glass melting furnaces

1. Erosion of fused cast AZS blocks in glass furnaces

Fused cast AZS blocks are mostly used in the highest temperature parts of the glass furnace and in the parts that are most severely eroded by the glass solution. Different block types are usually labelled by the amount of ZrO2 content. The blocks are mainly composed of α-corundum, two crystalline phases of plagioclase zircon and a glass phase. Plagioclase zircon is free except for eutectic with α-corundum. The more ZrO2 the block contains, the freer plagioclase zircon there is. Both crystalline phases have good erosion resistance, and the two crystalline phases are closely combined with a uniform and dense structure, resulting in stronger erosion resistance.

Due to the introduction of a small amount of Na2O in the block, which makes the mullite precipitation zone shrink, mullite crystal phase is difficult to precipitate, and the formation of glass phase filled in the above between the crystal phase. This glass phase by the erosion of high temperature glass liquid to generate a larger viscosity of sodium feldspar glass, due to which a certain amount of dissolved ZrO2 and greater viscosity. This layer of high viscosity of the glass is retained on the surface of the block, not easy to diffuse, thus protecting the block body. If the block crystallization is coarse, erosion is not easy to generate a high viscosity layer, the glass liquid is easy to penetrate the block, faster erosion of the block.

In some cases, the sidewall tiles are not one block for the entire depth of the side, but are built in layers, which gives rise to horizontal joints. The horizontal joints are susceptible to erosion. The erosion situation is different for fused cast AZS blocks and bonded clay blocks. Clay blocks are subjected to essentially the same erosion above and below the horizontal joints, whereas fused cast AZS blocks are subjected to severe erosion above the horizontal joints and less severe erosion below the horizontal joints, as shown in the figure below. This upward drilling-like erosion process is roughly as follows: the horizontal joints in the sidewall have gaps where molten gla

_1.jpg)

ss can easily enter, and then the blocks above the horizontal joints are eroded by the glass liquid from below to create a highly viscous protective layer. The protective layer tends to flow downwards under the effect of gravity. Due to the loss of the highly viscous layer, a new block surface is exposed and subjected to new erosion.There will be some air bubbles at the top of the eroded layer, thus intensifying the erosion. As a result of this repeated action, the blocks above the horizontal joint are subjected to strong upward borehole erosion. The blocks in the lower part of the horizontal seam do not lose their protective layer, and there are no air bubbles resting on the lower surface, so they are subject to less erosion. Nowadays, due to the increase in glass furnace temperature and the use of auxiliary electrofusion

and bubbling technology, the erosion above the horizontal seam is more serious. As a result, more whole sidewall block designs are used.

Fused cast AZS blocks manufactured in a reducing atmosphere have poor erosion resistance. This is due to the use of graphite electrodes and graphite furnace lining in electric furnaces, resulting in a reducing atmosphere, C and CO will make part of the Fe2O3, TiO2, SiO2 in the melt be reduced to a low-valent oxide, so that the component increases, and the softening temperature of the glass phase in the blocks will decrease by 100-150 ℃. When this kind of block is used at high temperatures, the viscosity of its glass phase is low, and it is easier to diffuse into the high-temperature glass liquid, so that the crystalline phase in the block loses its bond and enters the glass liquid, forming streaks and stones.

2. Erosion Characteristics of Fused Cast AZS Block in Electric Glass Furnace

Fused Cast AZS Block erosion is mainly divided into physical effect and chemical effect. Physical effect refers to the side wall of the glass furnace is repeatedly subjected to rapid cold and rapid heat during long-term operation, and its surface must undergo the process of shrinkage and expansion. Due to excessive fatigue, the structure of the fused cast AZS block is destroyed, resulting in the increase of surface cracks and loose structure. Therefore, it breaks and peels off under the action of air flow, material and glass liquid, and will repeat this process continuously.

The chemical effects on the corrosion of fused cast AZS blocks are more complex and severe and can be divided into four areas:

(1) Glass phase precipitation

The fused cast AZS blocks of the sidewall are subjected to high temperature molten glass treatment for a long time (> 1500 °C). On the one hand, the glass phase in the blocks gradually melts and precipitates (precipitation temperature of about 1150°C). On the other hand, the glass liquid containing Na2O alkaline glass liquid will invade into the block along the fine pores and cracks of the block body and diffuse and penetrate with the precipitated glass liquid, thus reducing the viscosity of the precipitated glass liquid, the mobility for Improved corrosion properties and extended depth.

(2) Skeleton damage

With the deepening of the depth of corrosion of the glass liquid, the skeleton minerals constituting the block body gradually penetrate and are surrounded by the glass liquid containing Na2O, and the skeleton begins to be corroded. The dissolved mullite decomposes into α-Al2O3 and SiO2, which then promotes the conversion of α-Al2O3 into β-Al2O3. With the increase of temperature, β-Al2O3 is completely dissolved in the molten glass, and the corundum is also destroyed, then broken, decomposed and partially melted. β-Al2O3 is gradually dissolved in the glass at high temperatures, and is hardly retained. As the glass continues to diffuse and penetrate, the microcrystals become free, some of which are carried away by the vitreous solution and may become vitreous crystals, while others are preserved. Although plagioclase can be dissolved in glass, its solubility is small. When the temperature fluctuates, ZrO2 crystallizes rapidly from the molten glass to form skeletal or bead-like crystals of plagioclase zeolite.

(3) Crystallization of new minerals

The composition of the original molten glass changes as the skeletal minerals of the block body are partially melted in the molten glass. Consequently, when the ratio of SiO2 -Al 2O3 -Na2O in the molten glass approaches the theoretical composition of nepheline, a large number of chalcocite crystals will precipitate.

(4) Invasion of nepheline

This is because the density of nepheline is less than that of the block, and as the nepheline crystals precipitate out, the block structure becomes looser and expands more in volume. Although the melting of some of the crystalline phases in the block increases the viscosity of the vitreous liquid and provides some protection against the loose structure, it still does not completely prevent the airflow, material and glass from washing away in the glass furnace. Liquid and gravitational forces, as well as cracking, flake it off into the molten glass and form glass stones. The stripped wound surface continues to be eroded and washed by the glass liquid and continues to be stripped. The result will inevitably be corrosion and disintegration of the molten fused cast AZS blocks.

3. Extension of service life of fused cast AZS blocks in electric glass melting furnaces

3.1 Mechanistic aspects of erosion of fused cast AZS blocks.

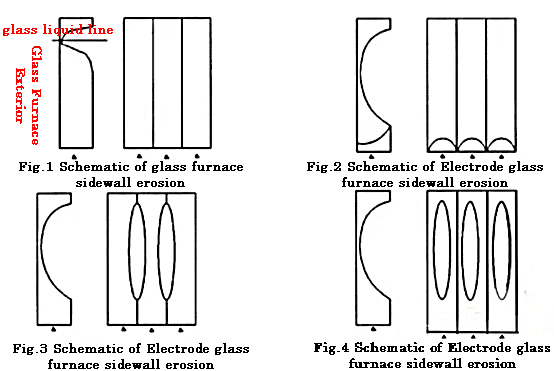

Glass furnace horizontal melting, material liquid surface moving horizontally, in addition to the throat in the three-phase interface at the serious erosion, as shown in Figure 1.

Glass electric melting furnace is vertical melting, most of them are cold top melting, the glass liquid surface is covered by a layer of raw material layer, there are fewer three-phase interface. As a result of vertical melting, the sidewall block erosion is no longer concentrated in the three-phase interface, but the overall erosion, so the weak link of the fused cast AZS block is the erosion of the breakthrough, as shown in Fig. 2 ~ 4.

For the erosion mechanism of fused cast AZS blocks, first of all, we should strictly control the content of Na2O in the raw material composition of fused cast AZS blocks. The national standard requires that the content of Na2O in 33#WS is below 1.45%, and that in 41#WS is below 1.3%, and the standard of our company‘s electrofusion furnace requires that the content of Na2O in 33#WS is below 1.40%, and that in 41#WS is below 1.2%.

For the erosion part of Figure 2, the ratio of riser and block material must reach 1.5:1, through the pressure of riser material, effectively reduce the residual porosity in the block material, enhance the anti-erosion ability of the block material at the injection opening, and require the injection opening to have no obvious shrinkage of the residual porosity.

Aiming at the erosion part of Fig. 3, in the process of assembling fused cast AZS blocks, strictly inspect the block seam, which is required to be below 0.3mm, and in the process of baking the glass furnace, strictly control the expansion difference of each part, to ensure that the block seam in the process of the degree of tightness, so as to reduce the gas entry, to prevent the formation of a three-phase interface at the block seam, and to alleviate the erosion of the part of Fig. 3.

For Figure 4 parts of the erosion, the design process requires that the width of the block is less than 400mm, too wide will lead to the existence of block internal shrinkage of the residual more than the internal sparsity; requirements of the risers and the ratio of the block must reach 1.5:1, through the pressure, the rate of gas discharged, to improve the quality of the internal block; glass furnace operation in the later stages to reduce insulation, by reducing the temperature of the block, reduce the erosion rate.

3.2 Structural aspects of glass furnaces

♦Optimization of glass furnace structure and design

Choosing the right type of glass furnace: Different glass formulations are suitable for different types of furnaces, and the erosion of the refractory materials by the forced convection of glass in the electric melting furnace should be fully considered in the design, so as to ensure the erosion resistance of the refractory materials in each part, especially the lining blocks, through reasonable structural design.

Optimization of electrode arrangement: The way in which the electrodes are inserted has a significant impact on the life of the glass furnace. For example,

The top insertion electrode is relatively less erosive, but the design and equipment requirements are higher;

The bottom insertion electrode is also less erosive, but the operation and maintenance are more difficult;

The flat insertion electrode block is more erosive, and if there is no special means of erosion on the glass furnace is more erosive.

Therefore, according to the actual situation should choose the appropriate electrode arrangement.

♦Reasonable control of use conditions

Control temperature fluctuation: During the warming and preheating period, the temperature should be raised in accordance with the heating curve, and the drawbar should be adjusted in time so that the fused cast AZS blocks in each part of the glass melting furnace expands uniformly. Especially in the interval of 850~1200℃, the temperature fluctuation should be as small as possible to avoid the fused cast AZS blocks blowing up due to the drastic temperature change.

Optimization of ingredients: Different ingredients have different levels of erosion of fused cast AZS blocks and electrodes. Therefore, the ingredients should be optimized to reduce the use of formulas containing titanium, barium, fluoride and other harmful ingredients to extend the life of the glass furnace.

♦Strengthen the maintenance

Regular inspection and maintenance: Regular inspection of the glass furnace, timely detection and treatment of the glass furnace body reddening, block seam seepage and other problems. At the same time, check and maintain the electrode water jacket and softened water to ensure that the water jacket does not leak.

Timely replacement of damaged parts: For the damaged fused cast AZS blocks, electrodes and other components, should be replaced in time to avoid further impact on the life of the glass furnace.

Avoid frequent material changes and power and water cuts: Frequent material changes and power and water cuts will adversely affect the glass furnace. Therefore, these operations should be avoided to minimize damage to the glass furnace.

♦Optimization of production process and operation

Operate in strict accordance with the process requirements: In the production process, the electric melting furnace should be operated in strict accordance with the process and thermal regime to avoid improper operation such as large fluctuations in output.

Strengthen the production management: strengthen the production management to ensure the stability and continuity of the production process so as to reduce the extra burden on the glass furnace.

3.3 Aspects of fused cast AZS blocks

Choose high-quality fused cast AZS blocks

Considering from the perspective of glass furnace life, high quality and high-grade fused cast AZS blocks should be preferred. According to the working conditions and erosion degree of different parts of the glass furnace, choose different materials of fused cast AZS blocks. For example, the bottom of the glass furnace can use fused cast AZS 33#blocks, while the throat and electrode blocks are used without shrinkage fused cast AZS 41#blocks.

Henan SNR Refractory Co., Ltd. is dedicated to the manufacturing and research and development of fused cast AZS refractory materials for the glass industry. Meanwhile, SNR can provide total solutions and services for glass furnace design, glass furnace construction, renovation and upgrading. Please contact me if you have any requirement.