The furnace bottom serves as the foundation of a glass melting furnace. Its health directly impacts the furnace‘s service life, glass quality, and production safety. Bottom corrosion is a complex and gradual physicochemical process. Once it occurs, repair is extremely difficult and can lead to catastrophic consequences. This article provides a systematic and in-depth analysis of the various causes of corrosion in glass furnace bottoms, covering electrochemical corrosion, chemical attack, mechanical erosion, and thermodynamic effects. It aims to offer a comprehensive and accurate reference for technical and management personnel within the industry, supporting efforts to achieve long-term, stable, and efficient furnace operation.

2. Core Mechanisms and Cause Analysis of Bottom Corrosion

3. Specific Influences of Different Glass Types on Bottom Corrosion

4. Comprehensive Protection Strategies and Recommendations

During the glass melting process, damage to the upper structures of the furnace, such as sidewalls, breastwalls, and crowns, is often more direct and observable. In contrast, corrosion of the furnace bottom is highly insidious. It occurs beneath meters of molten glass, beyond the reach of daily visual inspection. However, its potential consequences are severe:

Risk of Run-Out: Excessive thinning of the bottom refractory blocks due to erosion is the root cause of glass leakage. A run-out event can not only halt production lines but also trigger safety incidents and significant economic losses.

Contamination of the Melt: Eroded refractory material enters the glass melt in the form of stones, cords, or blisters, severely compromising the homogeneity and optical properties of the glass, leading to downgraded products or even total scrap.

Reduction of Furnace Campaign Life: The integrity of the bottom is a key factor determining the cold repair campaign of a furnace. Severe bottom corrosion is often the primary reason forcing an early furnace shutdown for major repair.

Increased Energy Consumption: Bottom corrosion can compromise the insulation layer or create abnormal hot spots, leading to increased heat loss and higher energy consumption.

Therefore, a deep understanding of the mechanisms behind bottom corrosion is a prerequisite for scientific material selection, operational optimization, and effective monitoring.

Bottom corrosion is not the result of a single factor but rather the synergistic effect of multiple mechanisms. The primary causes can be categorized as follows:

2.1 Electrochemical Corrosion – The Primary and Most Prevalent Mechanism

This is widely regarded as the dominant corrosion mechanism occurring in the bottoms of most glass melting furnaces today.

Formation Conditions: Molten glass acts as an ionic conductor at high temperatures. The furnace bottom typically consists of refractory blocks of different materials (e.g., Alumina-Zirconia-Silica AZS, fireclay, fused cast zirconia) and metal electrodes (e.g., molybdenum). Differences in electrochemical potential between these materials, with the glass melt acting as the electrolyte, create a complete "galvanic cell" or "electrolytic cell" circuit.

Corrosion Process:

Anodic Reaction: At locations with a lower electrode potential (e.g., fireclay backup lining, joint materials, or metal electrodes), oxidation occurs, losing electrons. For iron, for example:

Fe → Fe²⁺ + 2e⁻.

The generated Fe²⁺ ions dissolve into the glass melt.

Cathodic Reaction: At locations with a higher electrode potential (e.g., the ZrO₂ or corundum phases in AZS blocks), reduction occurs, gaining electrons.This is typically the reduction of multivalent ions present in the glass melt (e.g., Fe³⁺, As⁵⁺, Sb⁵⁺):

Fe³⁺ + e⁻ → Fe²⁺

Driving and Accelerating Factors:

Applied Electric Potential: The current introduced through bottom heating electrodes (e.g., molybdenum electrodes) significantly intensifies this electrolytic process, causing the surrounding refractory material to become the anode and dissolve rapidly.

Oxygen Concentration Gradient: A difference in oxygen partial pressure exists between the upper and lower layers of the glass bath. The surface layer has a higher oxygen partial pressure, while the bottom layer has a lower one. This difference creates an "oxygen concentration cell," causing the refractory material in the deeper, oxygen-depleted bottom layer (anode) to corrode relative to the surface layer (cathode).

Material Differences: Differences in electrochemical potential exist between different refractory materials (e.g., AZS vs. fireclay), between new and old blocks, and even between different microstructural phases within the same block (e.g., the corundum and glassy phases in AZS), leading to micro-galvanic cell corrosion.

Characteristic Manifestations: Electrochemical corrosion typically presents as uniform thinning, progressing in depth. It is often more pronounced at joints between different materials, around electrodes, and in the deeper regions of the bottom.

2.2 Chemical Attack – Direct Dissolution and Reaction at High Temperatures

This involves the direct chemical interaction between the refractory material and the molten glass and its vapors.

Direct Dissolution: Certain components of the refractory material dissolve directly into the glass melt. For instance, the corundum phase (Al₂O₃) in AZS blocks dissolves into the silicate melt at high temperatures, with the dissolution rate increasing exponentially with rising temperature. The viscosity and basicity (R₂O content) of the glass phase decisively influence the dissolution rate; high-alkali glasses are generally more aggressive.

Interfacial Reactions:

Formation of a Reaction Layer: At the interface between the refractory and the glass melt, a reaction layer with altered composition and structure forms. This layer often has higher viscosity and poorer fluidity. If it remains stable, it can act as a protective barrier. However, if process conditions are unstable (e.g., temperature or glass level fluctuations), this protective layer can be disrupted, exposing fresh brick surface and allowing continuous erosion.

Upward Drilling: This is a phenomenon specific to AZS refractories. Because the density of the glassy phase and eutectics in AZS is lower than that of the bulk glass melt, they can migrate upwards, driven by temperature and concentration gradients. This upward drilling can lead to the deposition of these phases at joints or the colder ends of the blocks, leaving behind a porous and weakened structure that facilitates further glass penetration and attack.

Vapor Condensation and Cyclic Corrosion: Alkaline vapors (e.g., Na₂O), boric oxide vapors (B₂O₃), sulfates, and other volatile species generated during melting can condense on colder surfaces of the superstructure and upper sidewalls, forming highly corrosive condensates. When these condensates drip back onto the glass bath, they can cause severe localized chemical attack on the bottom refractories at the drip points.

2.3 Physical and Mechanical Actions – "Accomplices" Accelerating Corrosion

Glass Flow and Erosion: Batch charging, melting, refining, thermal convection, and processes like bubbling or electric boosting induce significant glass melt flow. This flow continuously scours the refractory surface, washing away the formed reaction layer or the protective, high-viscosity layer, thereby continually exposing fresh brick surfaces and significantly accelerating both chemical and electrochemical corrosion. Areas near bottom bubblers, below the doghouse, and under hot spots are particularly prone to erosion-corrosion.

Metal Deposition and Crystallization Stress: Certain metal oxides from the batch or cullet (e.g., PbO, SnO₂, As₂O₃) can be reduced to their metallic form (e.g., Pb, Sn, As) in the cooler regions of the furnace bottom. These molten metal droplets, being very dense, can penetrate brick joints or pores. Upon cooling and solidification, they undergo significant volume expansion, generating immense stress that can crack and spall the refractory, opening pathways for subsequent corrosion.

Penetration and Structural Spalling: Under hydrostatic pressure and capillary action, the glass melt penetrates into the refractory through pores, micro-cracks, and joints. The penetrating glass reacts with deeper components of the brick, altering its phase structure and forming a altered layer with vastly different properties (e.g., thermal expansion coefficient) compared to the original refractory. During temperature fluctuations, stress develops between this altered layer and the original sound brick, causing the refractory to spall off in sheets or layers—a very severe form of degradation.

2.4 Thermodynamic and Operational Factors – Macro-Level Influences

Temperature: This is the foremost factor influencing all corrosion rates. According to the Arrhenius equation, reaction rates increase exponentially with temperature. An increase in bottom temperature of 50-100°C can potentially double or quadruple the corrosion rate. Therefore, maintaining a reasonable and stable bottom temperature is crucial.

Temperature Fluctuations: Frequent or severe temperature fluctuations cause thermal expansion and contraction in the refractories, generating thermal stress that accelerates the formation and propagation of micro-cracks. Simultaneously, it disrupts any stable protective reaction layers that may have formed, allowing corrosion to proceed unabated.

Glass Level Fluctuations: The refractory at the glass line on the sidewalls experiences simultaneous attack from the melt, the furnace atmosphere, and batch materials, making it a zone of intense corrosion. Frequent glass level fluctuations widen this corrosion band, accelerating wear. For the bottom, level fluctuations affect the hydrostatic pressure, thereby altering the penetration behavior of the glass melt.

3. Specific Influences of Different Glass Types on Bottom Corrosion

Different glass compositions have distinct corrosivities:

Soda-Lime-Silica Glass: High Na₂O content is aggressive towards alumino-silicate refractories. Additionally, sulfates introduced as fining agents can exacerbate both electrochemical corrosion and condensate attack.

Borosilicate Glass: B₂O₃ has high volatility at elevated temperatures, and the condensed boric acid is highly corrosive to most refractories.

Aluminosilicate Glass: While not inherently highly corrosive, achieving high-quality glass often requires higher melting temperatures, which in themselves accelerate all corrosion processes.

Lead Glass: PbO is easily reduced to metallic lead, leading to severe metal penetration and crystallization stress damage.

Electronic Glass / Specialty Glasses: Often contain multiple oxides (e.g., BaO, ZnO, SrO), whose combined chemical effects can produce unforeseen attacks on specific refractories.

Based on the above analysis, preventing and controlling bottom corrosion requires a systematic, multi-faceted strategy:

Scientific Material Selection and Optimized Design:

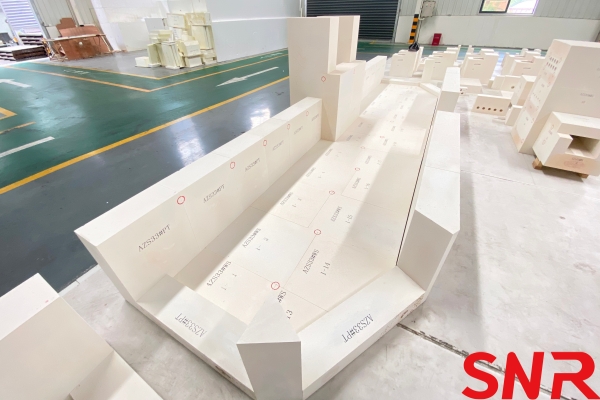

Reinforcement of Critical Zones: Use refractories with the highest corrosion resistance, such as 41# AZS with no shrinkage cavities (AZS 41 WS) or α-β/β-alumina blocks, in severely attacked areas like bubbling zones, electrode blocks, and the doghouse area.

Rational Block Design and Installation: Utilize large-size blocks to minimize joints. Employ dry laying or specialized jointing compounds, avoiding the use of ordinary mortars that are easily eroded.

Multi-Layer Composite Structure: Adopt a composite structure of "working lining + backup layer + insulation layer." The working lining resists corrosion, the backup layer (e.g., fireclay) acts as a safety barrier, and the insulation layer helps maintain bottom temperature, reducing condensation.

Precision Operation and Control:

Stable Thermal Regime: Maintain stable melting temperature, bottom temperature, and furnace pressure, avoiding significant fluctuations.

Stable Glass Level: Implement high-precision glass level control systems to minimize level variations.

Optimized Combustion and Bubbling: Properly position burners and bubblers to avoid excessive localized scouring of the bottom.

Control Reductive Atmospheres: Avoid creating excessively reducing atmospheres to prevent the reduction of metal oxides.

Proactive Monitoring and Early Warning:

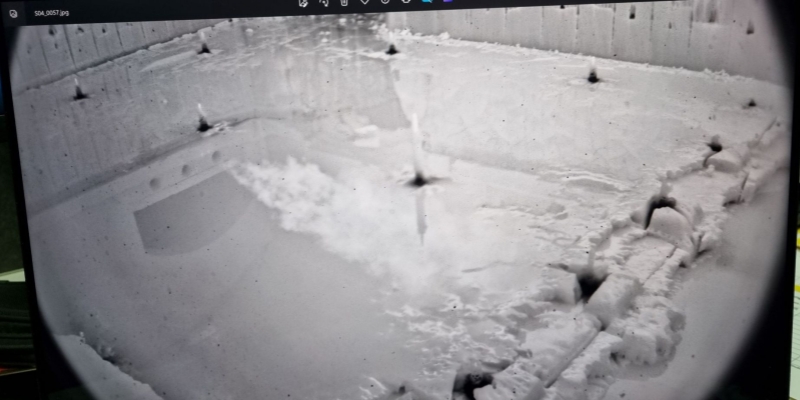

Bottom Temperature Monitoring: Embed thermocouples within the multiple layers of the bottom refractory structure to monitor temperature changes in real-time. An abnormal temperature rise is often an early warning sign of refractory thinning or potential leakage.

Electrode Current Monitoring: Monitor electrode-to-ground insulation and current distribution to prevent abnormal electrolytic corrosion due to decreased insulation.

Regular Non-Destructive Testing: Utilize techniques like endoscopy during cold or hot repairs to inspect the condition of the bottom.

Application of Advanced Technologies and Materials:

Bottom Bubbling: While it increases scouring, properly designed bubbling can prevent the accumulation of metal deposits on the bottom and enhance circulation in the lower melt layers, preventing the formation of "dead" stagnant zones.

High-Performance Insulation: Good insulation brings the hot face temperature of the bottom blocks closer to the glass melt temperature, reducing the interfacial temperature gradient, thereby slowing down glass penetration and condensate corrosion.

The corrosion of a glass furnace bottom is a complex process resulting from the intertwined effects of multiple factors: electrochemical, chemical, physical-mechanical, and operational. Among these, electrochemical corrosion plays an increasingly recognized critical role in modern furnaces, especially those with electric boosting.

For glass manufacturers, shifting the paradigm of bottom maintenance from "reactive repair" to "proactive prevention and control" is the essential path to extending furnace campaign life, ensuring production safety, and guaranteeing product quality. This requires close coordination across all stages—design, material selection, operation, and monitoring—forming a complete, lifecycle management system. Only in this way can the industry build a solid, long-lasting, and efficient industrial foundation capable of withstanding fierce market competition.

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for about 25 years. We use high-quality raw materials and advanced fusion technology to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

If you have any needs, you can contact me at any time.

If you have any needs, you can contact me at any time.

Web: www.snr-azs.com

Email:wendy@snrefractory.com