Against the global backdrop of carbon neutrality, the glass manufacturing industry, as a traditional high-energy-consumption sector, faces severe pressure to save energy and reduce emissions. Statistics indicate that during glass production, furnace energy consumption accounts for over 70% of total energy use, with fuel combustion contributing to 60%–70% of total CO₂ emissions. As carbon trading markets mature and environmental requirements tighten, advancing energy saving and emission reduction in furnaces has become an inevitable choice for enterprises to enhance competitiveness and achieve sustainable development.

This article systematically analyzes the technical pathways for energy saving and emission reduction in glass furnaces, exploring practical implementation solutions from dimensions such as energy efficiency improvement, fuel substitution, raw material optimization, and intelligent control, providing technical references and practical guidance for glass manufacturers.

1. Energy Efficiency Improvement Technologies

2. Fuel Substitution and Clean Energy

3. Raw Material Processing and Process Optimization

4. Intelligent Control Systems

1. Energy Efficiency Improvement Technologies

1.1 Combustion System Optimization

Oxy-fuel combustion technology is currently the most promising energy-saving technology. Compared to traditional air combustion, oxy-fuel combustion uses oxygen with a purity of over 93% as the combustion medium, eliminating heat loss caused by nitrogen. Actual operational data show that this technology can reduce fuel consumption by 20%–30%, decrease flue gas volume by approximately 80%, and increase melting rates by 15%–25%. Additionally, it significantly reduces NOx emissions and improves the working environment.

Key considerations for implementing oxy-fuel combustion include:

First, supporting oxygen generation systems, including vacuum pressure swing adsorption (VPSA) units or cryogenic air separation plants, require significant initial investment, but costs are typically recovered through energy savings within 2–3 years.

Second, burner design must be optimized, using special materials and cooling structures to adapt to the combustion characteristics of high-concentration oxygen.

Finally, a comprehensive training system must be established to ensure operators master new control strategies and safety protocols.

1.2 Waste Heat Recovery and Utilization

Waste heat recovery is a critical component for improving energy utilization efficiency. Modern glass factories should adopt a cascaded utilization principle for waste heat recovery:

The high-temperature segment (above 400°C) of flue gas should be used to generate steam via waste heat boilers for power generation or equipment operation. For instance, a float glass production line with a daily melting capacity of 600 tons can generate approximately 10 million kWh of electricity annually through waste heat recovery, meeting 30% of the plant‘s electricity needs. Advanced waste heat boiler systems are also equipped with automatic soot blowing devices to ensure long-term stable operation.

The medium-temperature segment (200–400°C) of flue gas can be used for cullet preheating. Innovative fluidized bed preheating systems can heat cullet to above 300°C, reducing melting energy consumption by about 12%. These systems typically include multi-stage preheating devices and precise temperature control to ensure uniform heating of the cullet while avoiding overheating and agglomeration.

The low-temperature segment (below 200°C) of flue gas can be upgraded via heat pumps for plant heating or domestic hot water supply. Using lithium bromide absorption heat pumps, low-temperature waste heat can be converted into usable heat sources at 60–70°C, with an overall system coefficient of performance (COP) reaching over 1.5, significantly improving energy utilization efficiency.

1.3 Furnace Structure Optimization

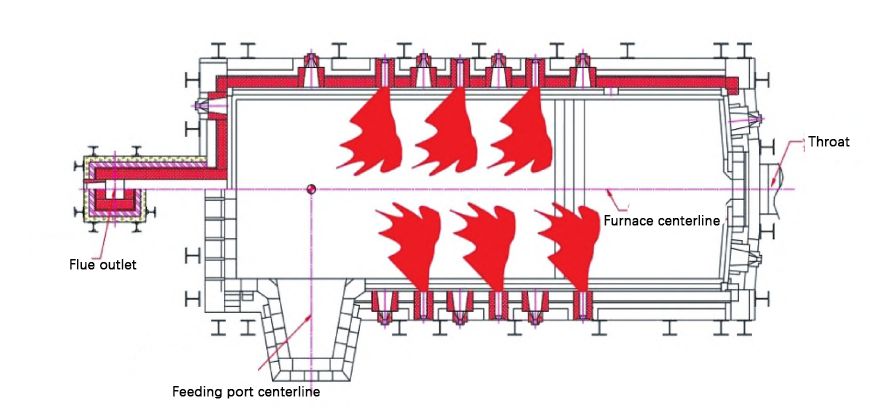

Optimizing furnace structure through computational fluid dynamics (CFD) simulations can effectively improve thermal efficiency. Modern furnace designs tend toward larger and flatter configurations, with length-to-width ratios controlled between 1.5 and 2.0. This structure facilitates stable glass flow fields and reduces energy loss caused by reflux. Through simulation analysis, burner arrangement angles and lance positions can be optimized to ensure uniform flame coverage.

In terms of insulation materials, new composite insulation materials can significantly reduce heat loss. For example, using aluminum oxide hollow sphere bricks as breast wall materials can reduce thermal conductivity to below 1.0 W/(m·K) while maintaining sufficient mechanical strength. Employing zircon bricks with nano-microporous insulation boards for sidewalls can control external surface temperatures below 80°C, a reduction of over 40°C compared to traditional structures. The furnace crown uses a multi-layer hanging structure with low-cement castables, ensuring structural stability while improving insulation effectiveness.

2. Fuel Substitution and Clean Energy

2.1 Natural Gas Substitution

Transitioning from heavy oil or coal gas to natural gas is currently the most feasible path to cleaner operations. Natural gas contains almost zero sulfur, preventing corrosion of refractory materials and contamination of glass products. Actual operational data show that after fuel conversion, product premium rates increase by over 2%, furnace lifespan extends by approximately 15 months, and maintenance cycles lengthen from the original 3 months to 6 months.

Key considerations for fuel substitution include: First, fuel supply systems must be modified, including constructing pressure regulation stations, laying dedicated pipelines, and updating metering devices. Second, burner designs must be optimized to adjust the air-to-gas mixing ratio for complete combustion. Finally, comprehensive safety monitoring systems must be established, including gas leak detection, emergency shut-off devices, and explosion-proof facilities to ensure operational safety.

2.2 Hydrogen Energy Applications

As a zero-carbon fuel, hydrogen holds broad application prospects in the glass industry. Implementation can be phased according to difficulty:

In the short term, blending 10%–20% hydrogen with natural gas can be adopted. Experimental data indicate that blending 15% hydrogen can reduce carbon emissions by about 6%. Due to hydrogen‘s fast flame propagation speed, combustion stability is improved, reducing incomplete combustion losses. This mode requires relatively low modification of existing equipment and is easy to implement.

In the medium term, transition to hydrogen-rich fuel combustion can be achieved by increasing the hydrogen ratio to over 50%. This phase requires developing specialized burners to address technical issues such as fast hydrogen combustion speed and short flame length, while also updating control systems and establishing hydrogen safety management systems. Storage and transportation systems also need upgrading, potentially requiring the construction of on-site hydrogen production facilities or liquid hydrogen storage tanks.

The long-term goal is to achieve pure hydrogen combustion, which requires breakthrough technological innovations and comprehensive hydrogen infrastructure. The European Union‘s "HyGlass" demonstration project has confirmed technical feasibility, achieving pure hydrogen combustion melting of glass in a laboratory environment, but the economic viability for large-scale industrial application still needs improvement.

2.3 Electric Boosting Technology

Electric boosting is a hybrid melting method that adds electrode heating to flame furnaces, particularly suitable for improving melting quality and increasing pull rates.

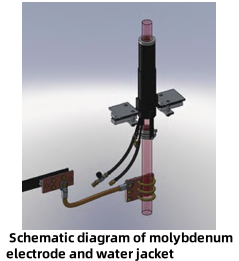

Electrodes are typically placed in hot spots, generating heat through the resistance effect of the glass melt. The proportion of electric boosting can be flexibly adjusted based on energy prices, generally ranging between 10% and 30%. When electricity prices are low, the proportion of electric boosting can be appropriately increased to reduce fuel consumption.

Key considerations for implementing electric boosting include: First, electrode placement positions and depths must be reasonably designed; molybdenum electrodes are usually used, placed 300–500mm below the glass melt level. Second, precise power control systems must be established, using thyristor power controllers to ensure stable power output. Finally, special attention must be paid to electrode cooling system maintenance, employing closed-loop water cooling systems and regularly checking water quality and flow rates to ensure operational safety.

3. Raw Material Processing and Process Optimization

3.1 Efficient Cullet Utilization

Increasing cullet usage is the most economical energy-saving measure. For every 10% increase in cullet usage, energy consumption can be reduced by approximately 2.5%, while also lowering raw material costs. To achieve efficient cullet utilization, a complete processing system must be established:

The pre-processing system includes crushing, screening, cleaning, and deironing processes. Modern processing lines employ multi-stage crushing combined with air separation, effectively removing impurities such as ceramics and metals. The application of optical sorting machines improves sorting accuracy to over 98%; CCD cameras identify off-color particles, and high-pressure air jets remove them, ensuring cullet quality.

The cullet preheating system innovatively combines waste heat utilization with raw material processing. New counterflow preheaters can heat cullet to above 400°C, with thermal efficiency exceeding 75%. Enterprise practices show that using preheated cullet not only reduces fuel consumption by 15% but also significantly improves the homogenization effect of the glass melt, reducing bubble defect rates by 20%.

3.2 Batch Optimization

Batch optimization directly affects melting energy consumption. Modern glass enterprises generally adopt the following measures:

The batching process improves heat transfer efficiency by compressing powdered batches into shapes. Practice shows that briquette melting can save 12%–18% energy compared to powder melting, and due to reduced raw material dusting, dust emissions decrease by over 90%. Modern briquetting machines use hydraulic servo systems, with forming pressures up to 100MPa, ensuring sufficient mechanical strength of the briquettes.

Scientific use of fluxing agents can effectively lower melting temperatures. New composite fluxing agents such as spodumene and fluorite can reduce melting temperatures by 50–100°C through eutectic formation. It should be noted that the addition of fluxing agents requires precise control, usually using online batching systems to ensure accurate proportions.

Batch preheating uses flue gas waste heat to preheat batches to 300–400°C, significantly reducing melting energy consumption. Innovative suspension preheating technology improves heat exchange efficiency by over 40% compared to traditional equipment, while also removing some volatile impurities.

4. Intelligent Control Systems

4.1 Advanced Control Systems

Modern glass furnace automation control systems have evolved from traditional PID control to model-based predictive control. System architecture includes:

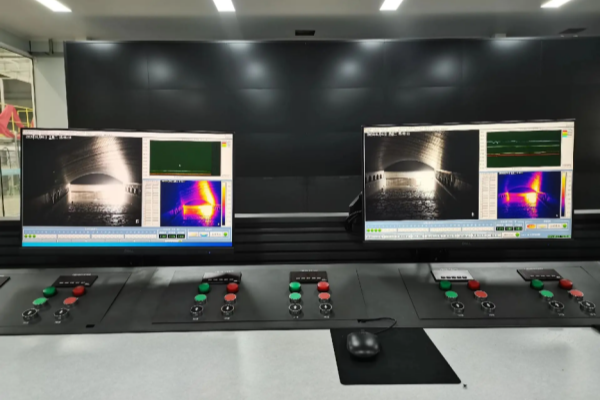

The sensor layer deploys various high-performance sensors, including high-temperature cameras, laser particle size analyzers, and online composition analyzers, enabling comprehensive perception of furnace operating status. Particularly noteworthy is the application of new fiber optic temperature sensors, enabling distributed measurement of the temperature field inside the furnace with an accuracy of ±1°C.

The control layer adopts hierarchical optimization strategies. The bottom layer uses improved fuzzy PID algorithms for stable basic parameter control, with response times less than 1 second. The upper layer employs model predictive control (MPC) for multi-variable coordination and optimization, completing global optimization calculations every 5 minutes.

The decision-making layer introduces digital twin technology to build virtual furnace models. Machine learning algorithms analyze historical data to continuously optimize operating parameters for ongoing energy efficiency improvements. One enterprise application showed that this system could reduce temperature fluctuations from ±10°C to ±3°C, lowering fuel consumption by about 5%.

4.2 Energy Management Systems

Comprehensive energy management systems are essential for continuous energy saving. Systems should include the following functions:

Real-time energy consumption monitoring collects electricity, gas, water, and other energy data through smart meters with sampling frequencies up to minute-level. The data processing module analyzes energy efficiency status through energy models, automatically identifies abnormal consumption, and issues timely warnings.

The energy efficiency benchmarking module establishes energy consumption benchmarks for different products and operating conditions, enabling refined energy efficiency management. Through horizontal and vertical comparisons, energy-saving potential is continuously identified. One glass enterprise discovered through its energy management system that compressed air systems accounted for 18% of total electricity consumption. After optimization, this was reduced by 30%, saving approximately 1.5 million yuan annually in electricity costs.

Energy saving and emission reduction in glass furnaces is a systematic project that requires coordinated progress across multiple dimensions including energy efficiency improvement, fuel substitution, raw material optimization, and intelligent control. Through scientific planning and phased implementation, glass enterprises can achieve significant energy conservation benefits and emission reduction effects while enhancing product quality and market competitiveness.

As hydrogen energy, carbon capture and other new technologies become more mature and cost-effective, the glass manufacturing industry is expected to achieve complete carbon neutrality. This process requires joint efforts from governments, enterprises, and research institutions to promote green, low-carbon, and circular development of the industry through policy support, technological innovation, and market drivers. It is recommended that government departments enhance support and introduce more incentive policies, enterprises should actively promote technological transformation and talent development, and research institutions should accelerate core technology research and development. Only through multi-party collaboration can the glass industry achieve high-quality sustainable development.

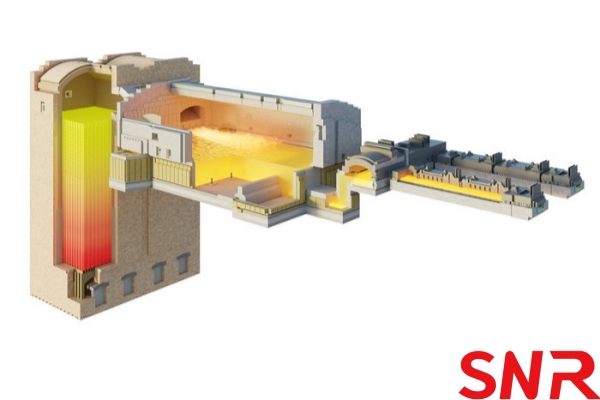

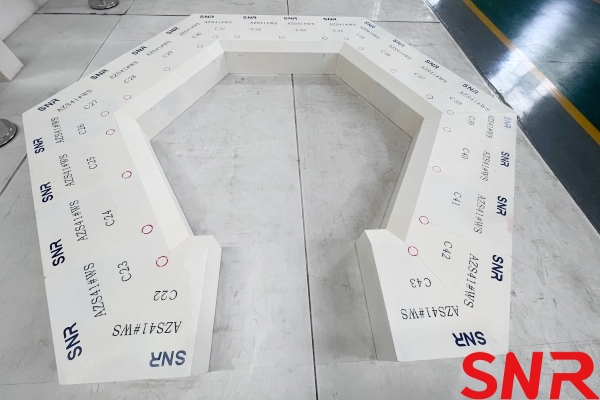

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for about 25 years. We use high-quality raw materials and advanced fusion technology to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

If you have any needs, you can contact me at any time.

If you have any needs, you can contact me at any time.

Web: www.snr-azs.com

Email:wendy@snrefractory.com