Glass manufacturing is one of humanity‘s oldest yet continuously evolving crafts. Within the classic thermal engineering apparatus of the regenerative (or "horseshoe flame") glass furnace, the batch undergoes complex physicochemical transformations into a homogeneous, transparent glass melt. The quality control of this transformation process directly determines the product‘s optical properties, mechanical strength, chemical stability, and production costs. The increasingly stringent requirements for product quality in the modern glass industry have made melting quality control a vital component of a glass manufacturing enterprise‘s core competitiveness.

This article systematically discusses the key elements of melting quality control in regenerative glass furnaces, delves into the intrinsic connections between various control links, and specifically explores the crucial role of fused cast AZS (Alumina-Zirconia-Silica) blocks in ensuring stable melting quality. Through a comprehensive analysis of aspects such as raw material preparation, combustion control, furnace design, refractory material selection, and process monitoring, it provides theoretical guidance and practical references for the efficient and stable operation of glass furnaces.

1. Source Control – Batch Preparation and Charging Technology

2. Energy Input Control – Optimization of the Combustion System

3. Process Intensification – Fluid Dynamics Optimization

4. Structural Assurance – The Critical Role of Refractory Materials

5. Thermal Management – The Balance of Insulation and Cooling

6. Process Monitoring – Data-Driven Quality Management

7. Comprehensive Optimization and Continuous Improvement

1. Source Control – Batch Preparation and Charging Technology

1.1 Precise Control of Raw Material Formulations

The chemical composition of the glass batch is the fundamental factor determining the final product‘s properties. Modern glass production utilizes computer-aided batching systems, capable of precisely calculating the proportions of various raw materials to ensure the stability of the glass chemistry. Strict quality inspections, including chemical analysis, particle size measurement, and moisture content testing of key indicators, are required for incoming raw materials. Particularly, controlling the content of coloring elements such as iron and chromium directly affects the glass‘s whiteness and light transmittance.

The uniformity of the batch directly influences the melting rate and the homogeneity of the glass melt. Modern glass factories employ high-efficiency forced mixers, optimizing mixing time, rotational speed, and feeding sequence to ensure the even distribution of all batch components. The assessment of mixing homogeneity is typically conducted through X-ray fluorescence spectroscopy or chemical titration methods, requiring that the content deviation of each component does not exceed ±0.5%.

1.2 Scientific Management of Cullet

Cullet, as a significant component of the batch, not only reduces raw material costs but also significantly promotes the melting process. The proportion of cullet addition is typically controlled between 15%-30%, depending on the glass type and production process. Cullet must undergo rigorous pretreatment, including cleaning to remove contaminants, sorting by color, and crushing to an appropriate particle size range (usually 5-20mm). Research indicates that cullet of suitable particle size can form a good melting skeleton, improving melting efficiency by approximately 10-15%.

The chemical stability of cullet is also a key consideration. Different batches of cullet may have compositional variations, requiring analytical testing and pre-blending to ensure relative stability in its chemical composition. Especially when producing specialty glasses like borosilicate glass, controlling impurities in the cullet is particularly important.

1.3 Fine-Tuning of Charging Technology

Thin-layer continuous charging technology is the standard configuration for modern regenerative furnaces. Using oscillating or blanket-type chargers, a uniformly thick layer of batch is formed in front of the hotspot area, achieving coverage of over 85%. This charging method enables the batch to heat up gradually and react in stages, avoiding volatile losses caused by local overheating.

The geometry and position of the batch pile significantly impact the melting process. The ideal batch pile should be close to the breast wall but not in direct contact, extending forward in a natural, gentle slope. A pile that is too long increases the melting burden, while one that is too short may cause the batch to disperse prematurely, reducing coverage efficiency. A vision system composed of laser rangefinders and industrial cameras can monitor the pile morphology in real-time and make automatic adjustments.

The stability of the glass level is the foundation for ensuring the stability of all process parameters. Using non-contact laser or radioactive level gauges coupled with PID control algorithms, level fluctuations can be controlled within a range of ±0.1mm. Stable level not only affects charging uniformity but also directly relates to the stability of heat distribution in the combustion space.

2. Energy Input Control – Optimization of the Combustion System

2.1 Fine Adjustment of Flame Characteristics

The combustion system is the core feature of a regenerative furnace. The flame‘s shape, length, rigidity, and brightness directly affect heat transfer efficiency and melting quality. By adjusting burner angle, fuel pressure, and atomizing medium parameters, a flat flame covering over 80% of the furnace width can be formed. The flame should have sufficient rigidity to avoid lifting or scouring the crown, while also ensuring adequate length to deliver heat to the furnace‘s rear section.

Modern furnaces are equipped with advanced combustion control systems that can adjust the fuel supply to individual burners in real-time based on the internal temperature distribution. Employing a feedforward-feedback composite control strategy can effectively compensate for heat fluctuations during reversal, maintaining temperature stability. Research shows that optimized combustion control can reduce fuel consumption by 3-5% while improving melting quality.

2.2 Establishment and Maintenance of the Temperature Regime

A clear temperature gradient is a key indicator of good operation in a regenerative furnace. From the doghouse to the hotspot, the temperature should show a steady increasing trend, typically with a rate of 15-25°C per meter; from the hotspot to the throat, the temperature should smoothly decline, forming the fining and homogenizing zone. The position and stability of the hotspot are crucial for melting quality. The ideal hotspot should be located at about two-thirds of the furnace length, with temperature fluctuations not exceeding ±5°C.

A multi-point temperature monitoring system provides comprehensive information on the furnace‘s thermal state. Beyond traditional thermocouples, the application of infrared thermal imagers and optical fiber temperature measurement technologies allows operators to obtain real-time temperature distributions within the combustion space and the glass melt. These data are translated, via advanced control algorithms, into precise adjustment commands for fuel valves, combustion air fans, and the reversal system.

2.3 Optimization Strategy for the Reversal Process

Periodic reversal is the basic operating mode of a regenerative furnace, but the reversal process is often accompanied by transient fluctuations in temperature and pressure. Optimizing reversal strategy is of great significance for stabilizing melting quality. Modern furnaces employ gradual reversal techniques, where fuel and combustion air on the new and old sides are cross-adjusted for a certain period before and after the reversal to achieve a smooth transition.

The choice of reversal cycle needs to comprehensively consider factors such as fuel type, melting load, and checker condition. Generally, the reversal cycle for natural gas furnaces is 15-25 minutes, while for heavy oil furnaces it can be appropriately extended to 25-30 minutes. By analyzing the temperature change curve during reversal, the heat storage capacity of the checkers can be evaluated, allowing for timely detection of blockage or damage issues.

2.4 Precise Control of Furnace Atmosphere

The furnace atmosphere has a decisive influence on the redox state of the glass. By adjusting the air excess coefficient, the valence state of iron in the glass can be controlled, thereby affecting the glass color and transmittance. Most soda-lime glass production employs a slightly oxidizing atmosphere, with the air excess coefficient controlled between 1.02 and 1.08; while some specialty glasses may require a neutral or even slightly reducing atmosphere.

Online gas analysis systems provide real-time data support for atmosphere control. Oxygen and CO analyzers installed at the regenerator outlet can continuously monitor flue gas composition, providing feedback information for combustion adjustments. Simultaneously, through precise control of furnace pressure (typically maintaining a positive pressure of 2-4 Pa), local atmosphere changes and heat loss caused by cold air infiltration can be prevented.

3.1 Guidance and Control of Natural Convection

The flow of glass melt in a regenerative furnace is primarily driven by natural convection. The density difference created by the high-temperature zone at the hotspot pushes the surface layer of glass melt back toward the doghouse, while the deeper layers flow toward the throat. This convection pattern plays a key role in the melting and homogenization of the batch.

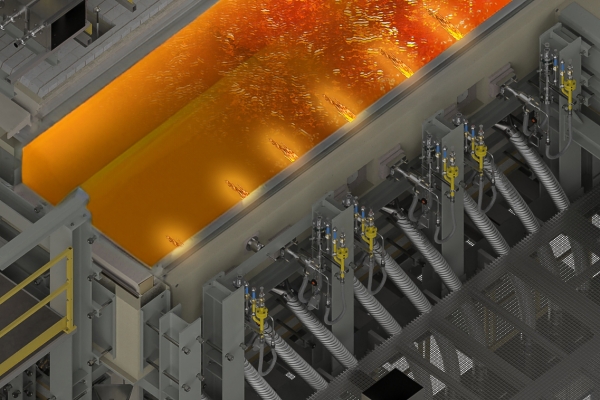

3.2 Application of Bubbling Technology

Bottom bubbling is a widely adopted homogenization technology in modern glass furnaces. By arranging bubblers in the bottom of the pre-hotspot area and injecting inert gas (usually nitrogen) into the glass melt, vertical bubble columns are formed. These columns generate intense agitation, capable of breaking up the stagnant bottom layer and promoting chemical and thermal homogeneity.

Bubbling parameters require fine-tuning. Bubble diameter is typically controlled at 5-15mm, and the bubbling frequency is adjusted according to furnace size and glass type, generally between 5-20 times per minute. Studies show that a properly configured bubbling system can improve glass melt temperature homogeneity by 30% and chemical homogeneity by 25%, while simultaneously reducing stone and seed defects by over 40%.

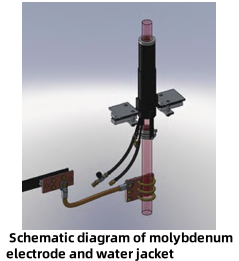

Electric boosting involves inserting electrodes into the glass melt to directly heat it using Joule heat. Supplementing conventional fuel heating with electric heating can significantly increase the temperature of the deep glass melt, enhance convection, and is particularly suitable for deep tanks or high-viscosity glass production.

Electrodes are typically placed in the hotspot area or charging zone, with electrode material (molybdenum or tin oxide) chosen based on glass type. Electric boosting power generally accounts for 10-30% of total energy consumption and can increase pull rate by 15-25% without increasing the heat load on the combustion space. This technology offers clear advantages in improving melting quality and reducing NOx emissions.

4. Structural Assurance – The Critical Role of Refractory Materials

4.1 Overview of the Refractory System

Refractory materials are the "skeleton" and "armor" of a glass furnace; their performance directly affects furnace campaign life, energy efficiency, and glass quality. Modern glass furnaces employ composite structures composed of various refractory types, with different materials selected for different areas based on the temperatures endured, chemical attack, and mechanical stresses.

Functionally, the refractory system mainly includes: melting zone refractories (in direct contact with high-temperature glass melt), superstructure refractories (enduring high-temperature gas attack), regenerator refractories (withstanding severe temperature fluctuations), and insulation materials (reducing heat loss). Each category has its specific performance requirements and selection criteria.

4.2 The Exceptional Performance of Fused Cast AZS Blocks

Among many refractory materials, fused cast AZS blocks (Al₂O₃-ZrO₂-SiO₂) are the preferred choice for critical areas of glass furnaces due to their excellent resistance to glass melt corrosion. Fused cast AZS blocks are produced by melting raw materials in an electric arc furnace at temperatures exceeding 2000°C, followed by casting into shapes and annealing. This manufacturing process gives them a dense microstructure, low porosity, and superior high-temperature properties.

The zirconia (ZrO₂) content in fused cast AZS blocks decisively influences their performance. Based on ZrO₂ content, they are graded as 33# (containing 33% ZrO₂), 36# (36% ZrO₂), and 41# (41% ZrO₂). As zirconia content increases, the material‘s corrosion resistance, thermal stability, and thermal shock resistance improve accordingly, though cost also rises. Among them, 41# fused cast AZS blocks possess the most outstanding overall performance and are commonly used in the most severely attacked areas of the furnace.

The corrosion resistance mechanism of fused cast AZS blocks is mainly reflected in the following aspects: Firstly, the dense microstructure formed by the zirconia-corundum eutectic effectively prevents glass melt penetration. Secondly, the ZrO₂ in the material forms a high-viscosity protective layer upon contact with the glass melt, slowing further attack. Thirdly, its excellent thermal stability ensures minimal cracking and spalling during temperature fluctuations.

4.3 Key Applications of Fused Cast AZS Blocks in Regenerative Furnaces

In a typical regenerative glass furnace, fused cast AZS blocks are primarily used in the following critical areas:

Throat Area: This is one of the most severely attacked areas in the furnace. Throat cover blocks, sidewall blocks, and bottom blocks are all made of fused cast AZS 41# block. Due to the high flow velocity, high temperature, and intense chemical attack in this area, the requirements for refractories are extremely high. Using well-integrated fused cast AZS blocks for construction, combined with appropriate cooling measures, can extend the throat service life to 5-8 years.

Doghouse Area: The doghouse corners and bottom are subjected to both mechanical abrasion from batch and cullet and severe temperature fluctuations. Using fused cast AZS 36# or 41# blocks can resist the initial attack from alkaline components in the batch and reduce maintenance frequency.

Hotspot Area Sidewalls: The sidewalls near the glass line in the hotspot area simultaneously endure corrosion from high-temperature glass melt and radiation from the flames above. Using fused cast AZS 41# blocks, combined with air- or water-cooling systems, can form a layer of frozen glass on the surface, significantly extending service life.

Bubbler Surroundings: The glass melt agitation is intense in the bubbling area, with an attack rate 2-3 times that of normal areas. Using specially designed fused cast AZS block protector sleeves can effectively protect the bubbler body and surrounding sidewalls.

Paving Blocks: The first layer of blocks in contact with the glass melt at the furnace bottom, especially near the throat, is also typically made of fused cast AZS blocks. High-quality fused cast AZS paving blocks ensure safe furnace operation in later campaign stages, preventing glass leak accidents.

4.4 Installation and Maintenance of Fused Cast AZS Blocks

The quality of installation directly affects the performance of fused cast AZS blocks. During installation, joints should be controlled to less than 1mm, filled with compatible AZS-based mortar. Joints are the weakest link most susceptible to attack; meticulous installation techniques can reduce the attack rate by over 30%.

Differentiated cooling strategies are developed based on the temperature and attack characteristics of different areas. For example, the throat area uses forced air cooling, while hotspot sidewall areas use natural air cooling or water-cooled jackets. By precisely controlling the cooling intensity, a protective layer of frozen glass is formed and maintained on the refractory surface.

Regular inspection of the erosion condition of fused cast AZS blocks is an important part of preventive maintenance. Using industrial endoscopes to observe the block condition and measure erosion thickness allows for predicting remaining life and planning repair schedules. When erosion reaches the designed safety thickness, timely hot repairs or planned furnace downtime for replacement is necessary.

4.5 Impact of Fused Cast AZS Blocks on Melting Quality

The application of high-quality fused cast AZS blocks enhances melting quality in several ways:

Chemical Stability: Fused cast AZS blocks have stable composition and release minimal impurities into the glass melt, avoiding defects like stones and cords caused by refractory corrosion. Research shows that using high-quality fused cast AZS blocks can reduce glass defects caused by refractories by over 60%.

Thermal Stability: Excellent thermal shock resistance ensures that during furnace temperature fluctuations or reversals, the refractory material does not crack or spall. Spalled refractory fragments entering the glass melt are a primary cause of stone defects.

Shape Retention: During long-term high-temperature service, fused cast AZS blocks maintain their original geometric shape, ensuring the stability of internal furnace dimensions. This is crucial for maintaining the designed glass melt flow field, directly impacting homogenization effectiveness.

Safety and Reliability: The high-temperature strength and corrosion resistance of fused cast AZS blocks ensure the structural integrity of the furnace, preventing accidents like glass leaks, and providing a guarantee for continuous, stable production.

5. Thermal Management – The Balance of Insulation and Cooling

5.1 Optimized Design of the Insulation System

Rational insulation design is of great significance for improving thermal efficiency and stabilizing the temperature field. Modern glass furnaces use multi-layer composite insulation structures, with each layer material selected based on service temperature and insulation requirements. A typical insulation structure, from inside to outside, includes: the dense working lining, transition layer, lightweight insulation layer, and reflective insulation layer.

The determination of insulation thickness requires a comprehensive balance between heat loss reduction and investment cost. Through heat flux density calculations and thermal imaging analysis, the insulation thickness for each area can be optimized. Research indicates that optimized insulation systems can reduce the furnace shell surface temperature by 80-120°C, decreasing radiant heat loss by 15-25%.

5.2 Scientific Application of Cooling Systems

Cooling and insulation may seem contradictory but are actually complementary. Applying appropriate cooling to critical areas can protect refractory materials and stabilize process conditions. Cooling system design follows the principle of "necessary, moderate, and controllable," avoiding energy waste caused by excessive cooling.

Air cooling is the most commonly used cooling method, involving blowing ambient air via fans to specific areas to carry away heat. Modern furnace air cooling systems are equipped with variable frequency drives and temperature feedback, automatically adjusting airflow based on refractory surface temperature. Water-cooled jackets are primarily used for extreme high-temperature areas, such as throat covers; their cooling efficiency is 5-8 times that of air cooling but requires more precise control to prevent thermal shock.

5.3 Heat Balance Analysis and Energy-Saving Measures

Establishing a heat balance model for the furnace is the foundation for optimizing energy utilization. By measuring input heat (fuel, electricity) and output heat (heat carried by glass, flue gas loss, radiation loss, cooling loss, etc.), weak links in energy use can be identified.

Energy-saving measures based on heat balance analysis include: optimizing combustion air preheat temperature, recovering waste heat from flue gases, improving insulation effectiveness, and rationally controlling cooling intensity. Comprehensive energy-saving modifications can achieve a 10-20% reduction in energy consumption while improving melting quality and stability.

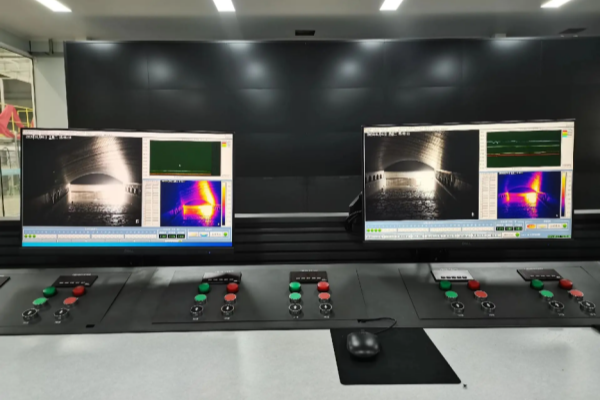

6.1 Construction of Online Monitoring Systems

Modern glass furnaces are equipped with comprehensive online monitoring systems that collect process parameters and quality indicators in real-time. Key monitoring points include: temperature (combustion space, glass melt, refractories), pressure (furnace pressure, fuel pressure), flow rates (fuel, combustion air, cooling media), level, gas composition (O₂, CO, NOx), etc.

The application of advanced sensing technologies has greatly improved monitoring accuracy and reliability. For example, non-contact infrared pyrometers can continuously measure the surface temperature distribution of the glass melt; laser spectrometers can analyze seed content and chemical composition online; high-definition industrial cameras coupled with image processing algorithms can automatically identify scum line morphology and batch pile status.

6.2 Data Integration and Intelligent Analysis

A Distributed Control System (DCS) integrates all monitoring data onto a unified platform, enabling real-time display, historical storage, and trend analysis. Through data mining and machine learning algorithms, underlying patterns can be discovered from massive process data, and abnormal conditions can be warned against.

For example, by analyzing temperature fluctuation patterns, the erosion state of refractories can be predicted; by monitoring the relationship between fuel consumption and pull rate, changes in melting efficiency can be assessed; by analyzing the frequency distribution of seed defects, the root cause of quality issues can be traced. These intelligent analyses provide a scientific basis for optimizing control and preventive maintenance.

6.3 Implementation of Advanced Control Strategies

Model-based predictive control (MPC) and artificial intelligence control are being applied in the glass industry. These advanced control strategies can handle complex processes with multivariable coupling, large time delays, and nonlinearity, achieving more precise and stable control performance.

Taking temperature control as an example, traditional PID control often has limited effectiveness in handling reversal disturbances. In contrast, model predictive control can predict temperature changes caused by reversal in advance and take preventive adjustment measures, controlling temperature fluctuations within ±3°C. Similarly, in batch quality control, feedback control systems based on spectral analysis can adjust raw material proportions in real-time, controlling chemical composition deviation within ±0.2%.

7.1 Multi-Objective Optimization Methods

The glass melting process is inherently a multi-objective optimization problem, requiring a balanced trade-off among competing objectives such as product quality, energy efficiency, equipment lifespan, and environmental impact. Conventional single-objective optimization is often insufficient due to the interdependence of these goals—improving one often comes at the expense of another. Advanced multi-objective optimization algorithms, such as genetic algorithms (GA) and particle swarm optimization (PSO), provide effective computational frameworks for solving this type of complex decision-making problem. These algorithms can simultaneously search for a set of optimal solutions, known as the Pareto front, which represents the best possible compromises among the different objectives.

By establishing a comprehensive simulation platform that integrates thermal, fluid dynamics, chemical reaction, and economic cost models, it becomes possible to evaluate the combined effects of various operating strategies in a virtual environment before real-world implementation. For instance, multiple interdependent parameters—including hotspot temperature distribution, bubbling intensity, electric boosting power, fuel distribution, and furnace pressure—can be simultaneously optimized. The aim is to identify operational settings that not only achieve the required glass quality standards (e.g., homogeneity, clarity, and defect levels) but also minimize energy consumption, reduce emissions, and extend refractory life.

This model-driven approach enables operators to explore a wider range of scenarios and make informed, data-supported decisions for sustainable and economically viable furnace operation.

7.2 Continuous Improvement System

Establishing a continuous improvement system based on the PDCA (Plan-Do-Check-Act) cycle is key to maintaining a high level of melting quality over the long term. This system includes: regular performance evaluation, root cause analysis, development of improvement measures, effect verification, and standardization.

Tracking and comparing Key Performance Indicators (KPIs) provide direction for improvement. Important melting quality KPIs include: energy consumption per ton of glass, melting rate, seed defect rate, stone defect rate, refractory erosion rate, etc. By comparing with industry best practices, gaps can be identified and catch-up plans can be formulated.

7.3 Personnel Training and Knowledge Management

Advanced technology and equipment require highly skilled operators and maintenance personnel. Establishing a systematic training system covering theoretical knowledge, operational skills, fault diagnosis, and safety regulations is fundamental to ensuring stable melting quality.

A knowledge management system makes tacit knowledge—such as expert experience, historical data, and best practices—explicit and systematic, preventing knowledge loss due to personnel changes. Through tools like case databases, decision support systems, and online training platforms, the professional capabilities of the entire team are enhanced.

Conclusion and Outlook

The control of melting quality in a regenerative glass furnace is a complex systems engineering challenge involving multiple disciplines and interconnected links. From batch preparation to combustion control, from fluid dynamics optimization to refractory material selection, each link significantly impacts the final melting quality. In particular, the application of high-performance refractory materials like fused cast AZS blocks provides fundamental assurance for stable production in high-temperature, high-corrosion environments.

Future developments in glass furnace melting quality control will trend toward greater intelligence, environmental sustainability, and efficiency. Virtual commissioning and optimization based on digital twins, adaptive control driven by artificial intelligence, and the development and application of new refractory and insulation materials will further enhance melting quality and energy efficiency. Simultaneously, with the requirements of the circular economy and low-carbon development, new technologies such as efficient cullet utilization, full oxy-fuel combustion, and deep waste heat recovery will see broader application in the glass industry.

Amid fierce market competition and stringent environmental regulations, glass manufacturing enterprises can only maintain their competitive advantage and achieve sustainable development by continuously optimizing their melting quality control systems and enhancing technological innovation capabilities. The control strategies and practical experiences systematically described in this article provide a comprehensive reference for the efficient and stable operation of glass furnaces, hoping to contribute to the technological progress and quality improvement of the glass industry.

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for more than 25 years. We use high-quality raw materials and advanced fusion and casting technology and equipment to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

Should you have any inquiries or specific requirements, our team is ready to provide professional support and tailored solutions.

Contact Information:

Contact Information:

Web: www.snr-azs.com

Email:wendy@snrefractory.com