When the glass liquid comes into contact with the fused cast AZS block, the fused cast AZS block with good quality, high density and strong corrosion resistance can reduce the interference of its own composition on the glass liquid, and can effectively prevent the glass liquid from penetrating into the internal bubble source. The poor quality fused cast AZS block may become a factor in the generation of glass bubbles due to erosion, pores and other problems. Although the fused cast AZS block has good corrosion resistance, it will still have a certain degree of erosion over time. The components in the fused cast AZS block may dissolve into the glass liquid, changing the composition and properties of the glass liquid.

For example, when components such as ZrO ² in an fused cast AZS block dissolve, it may affect the viscosity and other physical properties of the glass liquid, which in turn affects the solubility and discharge of the gas. If there are pores or brick slits in the fused cast AZS block itself, the glass liquid may penetrate. When conditions such as glass furnace temperature change, these gases trapped in the pores or brick slits may re-enter the glass liquid and form bubbles. Moreover, these pores also provide a place for the gases in the glass liquid to gather, making it easier for bubbles to form and grow. This article will analyze the relationship between fused cast AZS block and glass bubble formation from physical and chemical aspects and how to avoid this problem

1. Physical mechanism of fused cast AZS block and glass bubble formation

2. Chemical mechanism of fused cast AZS block and glass bubble formation

1. Physical mechanism of fused cast AZS block and glass bubble formation

1.1 Gas composition in fused cast AZS blocks pores

The inside of the fused cast AZS blocks contains many pores, and the inside of these pores is filled with gas. The composition of the gas is roughly the same as the composition of the air, mainly nitrogen, oxygen, and a small amount of carbon dioxide gas. As the contact time between the fused cast AZS block and the glass liquid is extended, due to the erosion of the surface of the block, the internal voids will be exposed, and the internal gas filled inside will be released to form bubbles.

The research on the erosion mechanism of refractory materials in the tube screen glass tank furnace shows that during the erosion of fused cast AZS block by the glass melt, the gases (N2, O2, CO2) in the closed gas hole of fused cast AZS block are released, and bubbles will also form in the glass melt. Under the condition of oxygen-assisted combustion, the erosion degree of fused cast AZS block by the glass melt of the picture tube screen is 30% larger than that under the condition of air-assisted combustion. It may be due to the formation of more moisture under the condition of oxygen-assisted combustion, which reduces the viscosity of the glass liquid and intensifies the erosion of the fused cast AZS block, resulting in more gas being released from the pores to form bubbles.

1.2 Fused cast AZS block impurity element oxidation to form bubbles

The fused cast AZS block contains impurity elements that can be oxidized to form gases, such as carbon, sulfur, zirconium carbide, nitrides, nitrogen oxides, etc. When the fused cast AZS block is heated to more than 1400 degrees, these impurity elements will undergo oxidation reactions to form corresponding nitrogen, carbon monoxide, carbon dioxide, sulfur dioxide and other gases. These gases enter the glass liquid and bubbles will form. This shows that the oxidation reaction of the impurity elements in the fused cast AZS block at a specific temperature will lead to the generation of glass bubbles.

1.3 Fused cast AZS block glass phase precipitation produces bubbles

The fused cast AZS block is the main refractory material used in the key parts of the masonry glass furnace, but the glass phase is easily eroded, which seriously affects the quality of the fused cast AZS block and the quality of the glass product. When we conducted high-temperature microscopy research on the fused cast AZS block, we found that the fused cast AZS block began to precipitate the glass phase when the temperature reached more than 1100 ° C, and began to precipitate bubbles at about 1225-1340 ° C.

The glass phase plays a role in glass production as a melting aid, relaxing the thermal stress generated during annealing, and the stress generated by the phase transition, preventing cracking and improving the product qualification rate. However, the glass phase is easily eroded, and once eroded, it will reduce the corrosion resistance and thermal shock stability of the fused cast AZS block.

For example, in the ultra-white float glass production line, due to the good thermal conductivity of ultra-white glass, the bottom temperature is high, and the convection intensity in the horizontal direction is large, which seriously erodes the fused cast AZS block at the paving and sidewall, which is easy to form bubbles, increase production costs, and affect the quality of the glass.

1.4 Why are fused cast AZS blocks easy to burst?

In the use of fused AZS flow nozzles, a company used fused cast AZS blocks, but stopped using them for a period of time due to the explosion of fused cast AZS blocks and the overflow of bubbles. After research, it was found that there are many open and closed pores in fused cast AZS blocks, accompanied by cracks. When in contact with the glass liquid, the molten glass liquid erodes the surface of the fused cast AZS block, causing the closed pores to become open pores. This allows the gas in the pores to be expelled and enter the glass liquid to form bubbles. If the porosity is relatively high, and the temperature of the glass liquid entering the flow nozzle is around 1220 ° C, the gas will be released for a long time, so that the bubbles cannot be eliminated.

♦First of all, fused cast AZS block has good thermal conductivity. After the whole process of glass furnace heating ultra-low temperature drainage pipe is completed, if the temporary pre-insulation of the crown is not carried out in time, the temperature of the outer layer of the crown is lower, and the internal temperature of the arch is higher, which will lead to uneven temperature and cause bursting.

♦Secondly, the temperature rise curve must be strictly enforced to avoid large fluctuations in temperature, especially after a fire. This is the critical moment for the large expansion of the fused cast AZS block, and the large change in temperature will lead to the bursting of the block. In addition, the zirconia in the fused cast AZS block has a phase transition at about 1200 ° C to produce contraction, and the structure is dense and there is less buffer phase, which also increases the possibility of bursting. For example, the temperature change of the tongue arch part of the port will fluctuate rapidly between 1000 and 1600 ° C, causing the tongue arch part of the fused cast AZS block to appear in different degrees of bursting and peeling phenomenon.

2. Chemical mechanism of fused cast AZS block and glass bubble formation

2.1 Fused cast AZS block variable valence elements and temperature changes form bubbles

The fused cast AZS block contains impurity elements that can be oxidized to form gases, such as carbon, sulfur, zirconium carbide, nitrides, nitrogen oxides, etc. When the AZS refractory brick is heated above 1400 ° C, these impurity elements will undergo oxidation reactions to form corresponding nitrogen, carbon monoxide, carbon dioxide, sulfur dioxide and other gases.

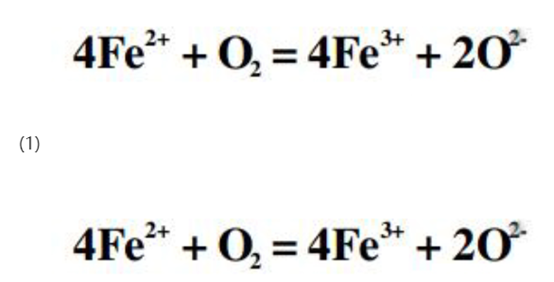

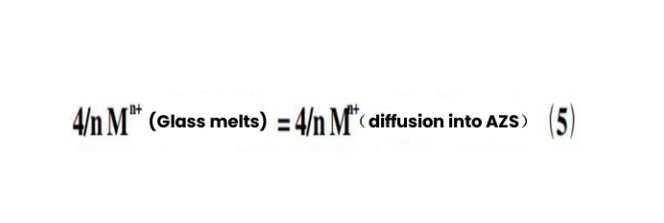

When the fused cast AZS block cools and heats up again, oxygen bubbles and secondary bubbles are generally generated at the contact between the molten glass and the fused cast AZS block. This is because under normal circumstances, fused cast AZS blocks contain a small amount (< 0.3% (mass fraction)) of variable valence elements, such as iron (Fe, Fe) or titanium (Ti, Ti). These variable valence elements can change their valence states with changes in temperature, thereby completing the role of absorbing or releasing oxygen. Such as reaction equation (1).

When the temperature decreases, the reaction equation (1) proceeds in the positive direction, which is conducive to the formation of Fe3 +; when the temperature increases, the reaction equation proceeds in the opposite direction, which is conducive to the formation of O2.

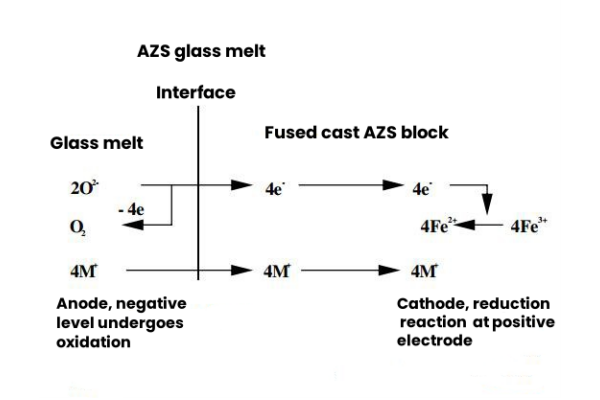

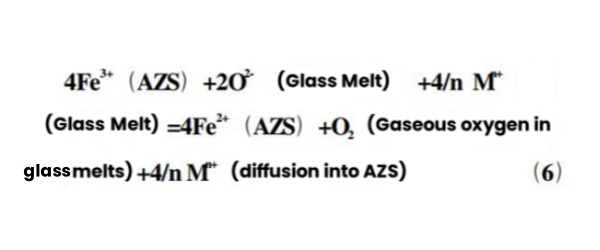

Another reason for the generation of oxygen is the electrochemical reaction between the glass liquid and the fused cast AZS block, or the "remote" electrochemical reaction in the case that the glass liquid does not contact the fused cast AZS block, which is responsible for the transfer of electrons by alkali metal or alkaline earth metal ions.

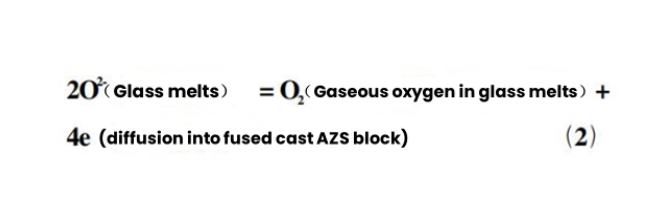

In this battery reaction, oxygen ions (O2) in the glass melt are oxidized to oxygen (O2), which is an anodic reaction:

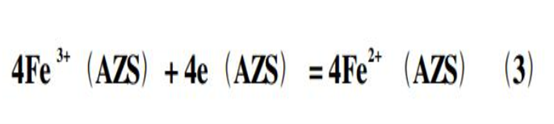

Highly valent iron (Fe3+) or titanium (Ti4+) in the fused cast AZS block is reduced, that is, the cathodic reaction:

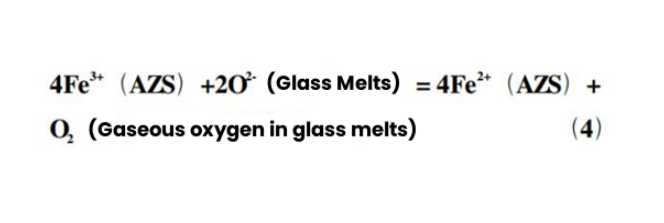

Overall chemical reaction:

The reaction rate of this electrochemical reaction is proportional to the content difference of alkali metal or alkaline earth metal ions in the glass melt and the fused cast AZS block.

When the glass melt comes into contact with the fused cast AZS block, the concentration of alkali metal or alkaline earth metal ions in the glass melt is much higher than that in the fused cast AZS block, and the glass phase exudes, so these metal ions Mn + will diffuse into the fused cast AZS block. The result is neutralization with the electrons that diffuse into the fused cast AZS block, maintaining electrical neutrality.

The process of this battery reaction can be depicted in Figure 1.

The equation (4) and equation (5) are combined to form the total chemical reaction equation for the battery reaction process shown in Figure 1.

2.2 The residual air released in the pores of fused cast AZS block forms bubbles

After we randomly selected ultra-white glass defect samples for testing, we found that the bubbles were in the middle and lower part in the thickness direction of the glass plate, the bubble diameter was distributed in 0.5~ 2.0mm, and there were inconspicuous deposits in the bubbles.

The bubbles mainly contain N2, CO2 and Ar, etc. It can be judged that the generation of bubbles is related to the residual air released from the pores of the refractory due to the erosion of the fused cast AZS block. The defective sample bubbles have a high content of N2, and the ratio of N2/Ar is consistent with the ambient air, indicating that they are air-related bubbles. The fused cast AZS block pores usually contain air.

When the fused cast AZS block is melted under reduction conditions, the O2 in the pores will be converted into CO2 or a mixture of CO2 and CO.

Once the pores are opened, the O2 in the pores comes into contact with the glass melt and is preferentially absorbed by the reducing components in the glass melt. The bubbles will contain a high concentration of N2, 0~ 20% CO2 by volume, and about 1% Ar by volume. The bubble diameter is 0.5~ 2.0mm, the CO2 content is low, and the bubbles are located in the middle and lower part of the thickness of the glass plate, indicating that the bubbles stay in the furnace for a short time.

It can be judged that the location of bubble generation may be downstream of the hot spot area. In the medium and high temperature or medium temperature area of the furnace, the most likely is between the end of the clarification area and the neck, and local refractory erosion occurs. It is also possible that the glass liquid penetrates the gap of the fused cast AZS block.

3. How to reduce the corrosion of fused cast AZS block on the glass to avoid the generation of glass bubbles

In order to reduce the corrosion of fused cast AZS blocks on glass and avoid the generation of glass bubbles, the following aspects can be considered:

3.1 Selection of high-quality fused cast AZS blocks

Select fused cast AZS blocks with low porosity to reduce the possibility that gas in the pores will be squeezed into the glass liquid when it comes into contact with the glass liquid. Try to choose fused cast AZS blocks with low impurity content, especially to reduce those impurity elements that can oxidize to form gases, such as carbon and sulfur.

3.2 Optimize the use of fused cast AZS blocks

►Rational laying: When fused cast AZS block in a glass furnace, ensure that the material is laid flat and seamless to reduce the passage of metal ion diffusion.

►Use composite layer: Use the same ramming material as the crystal phase of fused cast AZS block to form a sealing layer and a dead brick joint under the pavement block to form a complete composite layer resistant to glass liquid erosion.

►Layered configuration: The sidewall of the melted end is divided into two layers. The upper layer is made of 41 #fused cast AZS block and the content of silica is controlled below 13.5%. The lower layer is made of 33 #fused cast AZS block to increase the content of zirconia to above 33% and control the content of silica below 15%.

►Addition of stabilizer: Adding a small amount of Y₂O₃ as a stabilizer to the fused cast AZS blocks can significantly improve the microstructure of the material, increase the stability of ZrO₂ crystals and co-crystals, and thus enhance the resistance of the material to the erosion of glass liquid.

3.3 Improving the working environment of glass furnaces

Keep the temperature system of the glass furnace stable to avoid excessive temperature or excessive fluctuations to reduce thermal shock and erosion of fused cast AZS blocks. Strictly control the metal impurity content in the mix and broken glass to prevent metal particles from drilling down to erode fused cast AZS blocks.

3.4 Improve the corrosion resistance of fused cast AZS blocks

Improve the overall performance of fused cast AZS blocks by developing new materials with higher refractory temperatures and stronger corrosion resistance. Optimize the production process of fused cast AZS blocks to reduce defects and impurity content in the production process, thereby improving their corrosion resistance.

3.5 Enhanced maintenance and inspection

►Regular inspection: Regularly inspect the glass furnace and fused cast AZS blocks to detect and deal with potential erosion problems in a timely manner. For fused cast AZS blocks that have been severely eroded, they should be replaced in a timely manner to prevent further impact on glass quality.

►Observe the quality of the glass: Strengthen the observation of the quality of the glass. If any defects such as bubbles are found in the glass, the cause should be immediately analyzed and appropriate measures should be taken.

3.6 Enhanced cooling measures

According to the running time of the glass furnace and the erosion of the sidewall, the air volume of the cooling air is increased in stages to slow down the erosion rate of the fused cast AZS blocks. When designing the cooling system, the cooling air of the sidewall in the melting end is divided into two sections, and different cooling fans are set to cool the sidewall to improve the cooling effect.

3.7 Improve construction technology

Appropriately increasing the size of the sidewall blocks can reduce the number of block joints, thereby reducing the risk of glass liquid eroding the fused cast AZS blocks through the block joints. During the construction process, the size of the fused cast AZS blocks joints should be strictly controlled to ensure the uniformity and sealing of the fused cast AZS blocks joints.

3.8 Reasonable selection of brick binding material

When binding bricks to the sidewall, factors such as the age of the glass furnace, the ablation

of fused cast AZS blocks in other parts, the production status, and the blockage of the lattice body should be comprehensively considered, and the material and specifications of the binding bricks should be reasonably selected to improve the overall performance and lifespan of the glass furnace.

In summary, the comprehensive application of various measures such as optimizing the configuration of fused cast AZS blocks, strengthening cooling measures, improving construction technology, strengthening glass furnace inspection and glass quality observation, and rational selection of brick binding materials can effectively reduce the corrosion of fused cast AZS blocks on glass and avoid the generation of glass bubbles.

At the same time, the rational selection and use of fused cast AZS block, combined with the correct glass melting process, can control the generation of glass bubbles to a certain extent and improve the quality of the glass.

Henan SNR Refractory Co., Ltd (SNR) is professional in producing high-quality Fused Cast AZS Blocks for glass furnaces. If you have any needs, please contact me!

zoe@snrefractory.com

zoe@snrefractory.com