For a long time, glass furnaces have used air as the combustion-supporting gas, and the use of air as the combustion-supporting gas is the main cause of high pollution and high energy consumption.

Because the oxygen content in the air is only 21%, the remaining 78% of nitrogen is inefficiently heated during the glass melting process and discharged into the atmosphere at high temperature. In order to solve the problems caused by air combustion, full oxygen combustion technology has gradually been promoted around the world.

What is oxy-fuel combustion technology?

The so-called full oxygen combustion technology refers to a furnace that uses pure oxygen instead of air as the combustion-supporting gas.

Air combustion: CH4 + 2O2 + 7.5 N2 → CO2 + 2H2O + 7.5 N2

Full oxygen combustion: CH4 + 2O2 → CO2 + 2H2O

Glass furnaces using full oxygen combustion technology emit less exhaust gas and take away less heat;

the combustion is complete, there is no port and regenerator in the furnace structure, so the heat dissipation to the outside is less, and the energy saving effect is obvious. It usually saves 15~25% energy compared with air combustion.

The water vapor content in the combustion products of full oxygen combustion is higher than that of air combustion. The increase in water vapor content causes a series of changes in the glass melting furnace, which accelerates the erosion of refractory materials in the glass furnace.

This article takes fused cast AZS blocks as an example to compare the erosion process of fused cast AZS blocks in air combustion furnaces and analyzes the mechanism of accelerated erosion.

Ⅰ Overview of oxy-fuel combustion

Ⅱ Erosion process of AZS blocks in air combustion glass furnaces

Ⅲ Erosion process of AZS blocks in Oxy-fuel glass furnaces

ⅠOverview of oxy-fuel combustion

Under ideal conditions, the water vapor content in the products of oxyfuel combustion (taking natural gas as an example) is quite high, accounting for 67% of the total flue gas volume, which is 3.5 times the water vapor content in the products of air combustion. Due to the effect of water vapor, the following changes occur in the glass furnace.

1.1 Changes in the properties of molten glass

Oxygen combustion produces a large amount of water vapor, which increases the concentration of OH- dissolved in the molten glass, thereby changing the properties of the molten glass:

(1) Reduced the viscosity of the molten glass.

Studies have shown that the temperature of the isovensity line in the oxyfuel combustion soda-lime glass furnace is reduced by about 5°C. That is to say, when oxyfuel combustion uses the same melting temperature as air combustion, the viscosity of the molten glass in the oxyfuel combustion furnace is reduced.

(2) Reduced the concentration and surface tension of the molten glass.

(3) Increased the separation and crystallization tendency of the glass phase in the molten glass.

1.2 Changes in the flow of molten glass in the glass furnace

Due to the reduction in the viscosity of the molten glass, the surface tension and concentration of the molten glass, the convection speed of the molten glass in the glass furnace is increased.

1.3 The generation of glass liquid surface phenomena

Under the condition of full oxygen combustion, the combustion products contain a large proportion of H2O. The increasing water vapor reacts with some components on the surface layer of the glass liquid to produce more and more volatile hydroxides that escape from the liquid surface.

Ⅱ Erosion process of AZS blocks in air combustion glass furnaces

In glass furnaces, fused cast AZS blocks are mainly used for side walls and breast walls of melting parts.

2.1 Erosion process of fused cast AZS blocks for side wall

(1) Temperature effect:

There are more glass phases in fused cast AZS blocks. This glass phase has a low melting point and it seeps out of the blocks at high temperatures. The seepage temperature of fused cast AZS blocks made by reduction process is generally around 1100℃ and the seepage temperature of fused cast AZS blocks made by oxidation process is only around 1400℃. Therefore, in a high-temperature glass furnace of nearly 1600℃, a large amount of glass phases will continuously seep out of the refractory blocks. The crystal phases in the blocks become isolated and fall into the glass liquid under the action of self-weight and liquid flow.

(2) Chemical erosion:

The main components of molten glass that corrode fused cast AZS blocks are alkaline oxides Na2O and K2O. They not only reduce the liquid phase seepage temperature, but also undergo a replacement reaction with Al2O3 in the fused cast AZS block to produce nepheline and β-Al2O3. As this reaction proceeds and the glass phase seeps out, the ZrO2 and Al2O3 in the block are brought into the molten glass and form a high-viscosity inert protective layer on the surface of the block. This inert protective layer delays the further erosion of the block by the molten glass to a certain extent. However, this inert protective layer is very unstable.

On the one hand, it sinks into the molten glass due to its own weight, and on the other hand, it leaves the block surface due to the scouring of the liquid flow. The departure of the protective layer allows this chemical erosion to further develop into the block.

(3) Physical erosion:

There are two main types of physical erosion. One is that the vertical and horizontal flow and vertical convection of the glass liquid cause the refractory material to suffer mechanical wear; the other is that the existence of bubbles in the glass liquid produces upward drilling effect on the joints and cracks of the blocks.

2.2 Erosion process of fused cast AZS blocks for breast wall

(1) The scouring of the flame in the glass furnace causes mechanical wear on the breast wall, but this wear is much lighter than that on the side wall blocks.

(2) In the flame space of the glass furnace, due to the impact of the hot air flow, a large amount of alkaline powder is caused to fly, causing some Na2O and K2O to adhere to the surface of the breast wall blocks and continuously react with certain components of the breast wall blocks to cause chemical corrosion. In addition, the alkaline vapor in the flame space directly enters the interior of the blocks from the block joints and open pores, causing chemical corrosion.

(3) The closed bubbles in the blocks and the gas formed by the oxidation of the residual carbon in the blocks expand rapidly at high temperatures and squeeze out the liquid phase in the blocks. This process is related to the combined effect of temperature and alkaline vapor, causing a large amount of liquid phase to seep out of the blocks, while the crystal phase in the blocks becomes isolated and continuously falls into the glass furnace.

Ⅲ Erosion process of AZS blocks in Oxy-fuel glass furnace

The erosion process of refractory materials in oxyfuel glass furnace is basically the same as that in air combustion glass furnace, but the high concentration of water vapor in oxyfuel combustion products makes these processes more intense.

3.1 Erosion process of fused cast AZS blocks for side wall

(1) As OHˉ in water vapor continuously melts into the glass liquid, the viscosity and surface tension of the glass liquid are reduced, resulting in the rapid infiltration of Na2O and K2O in the glass liquid into the block. This infiltration process not only changes the glass phase composition of the refractory material, but also reduces the glass phase seepage temperature, resulting in an accelerated erosion rate of the refractory material.

(2) Due to the reduction of the viscosity and surface tension of the glass liquid, the convection speed of the glass liquid in the glass furnace is accelerated, which intensifies the mechanical wear of the side wall refractory material.

(3) A large amount of water vapor in the oxyfuel combustion products reacts with the components of the surface layer of the glass liquid to form volatile hydroxides that continuously escape from the surface of the glass liquid, intensifying the erosion of the three-phase liquid surface line of the side wall. According to a study by a certain refractory company in the United States, the erosion rate of side wall blocks in an oxyfuel glass furnace is 25% faster than that in an air combustion glass furnace.

3.2 Erosion process of fused cast AZS blocks for breast wall

The erosion process of fused cast AZS blocks for breast wall in an oxy-fuel glass furnace is basically the same as that in an air combustion glass furnace. On the one hand, the effect of water vapor reduces the liquid phase seepage temperature in the blocks; on the other hand, the reduction in the amount of flue gas reduces the chemical erosion of the blocks by alkaline flying materials and alkaline vapor. According to the data, there is not much difference in the erosion rate of the upper blocks in these two glass furnaces.

►Due to the high reaction temperature, thick raw material reaction foam, and direct erosion and corrosion by the mixed material, glass liquid and flame space, the service life of the refractory materials of the oxy-fuel combustion glass furnace will be seriously affected if it is improperly operated, controlled or maintained, and even cause major safety hazards. In addition, during the erosion of the side wall blocks, the detached refractory materials enter the glass liquid and form refractory stones, which pose a great safety hazard to the rollers of the calender. If the stones are not detected in the first time and enter the tempering furnace at the back end, it is easy to cause explosion, which seriously affects the quality and quality of the glass products.

Therefore, comprehensive consideration should be given to material selection, raw materials, furnace process system and other aspects to control or alleviate the erosion of the side wall blocks and maximize the service life of the oxy-fuel glass furnace.

Therefore, comprehensive consideration should be given to material selection, raw materials, furnace process system and other aspects to control or alleviate the erosion of the side wall blocks and maximize the service life of the oxy-fuel glass furnace.

Ⅳ Summary

According to the above analysis, for oxy-fuel glass furnaces, the accelerated erosion of the side wall and breast wall not only shortens the life of the glass furnace, but also increases the defects of the glass.

In order to extend the service life of the glass furnace and produce high-quality glass liquid, it is necessary to select fused cast AZS blocks with good chemical stability, low liquid phase (glass phase) content and high liquid phase seepage temperature.

With the continuous development of glass furnace technology, more and more pursuit of simplified operation, environmentally friendly emissions and efficient use, oxy-fuel combustion has also become a development trend. However, due to the high temperature and rapid erosion of oxy-fuel glass furnaces, it must be taken seriously in daily production and maintenance. Especially for the protection of side wall blocks, the material selection should keep pace with the times and choose new  fused cast AZS refractory materials that are more in line with the characteristics of full oxygen combustion;

fused cast AZS refractory materials that are more in line with the characteristics of full oxygen combustion;

►in process control, it is necessary to combine the advantages of full oxygen combustion glass furnaces, make reasonable layouts, formulate corresponding process systems and material recipes, and control the melting temperature; in glass furnace maintenance, more inspections and temperature measurements should be carried out, especially in the later stage of glass furnace operation, inspections and maintenance should be strengthened, and hidden dangers should be repaired in time;

►in the hot repair of side wall blocks, different hot repair methods should be adopted according to the different erosion conditions of different parts to ensure the safety of the glass furnace as much as possible and extend the service life of the glass furnace.

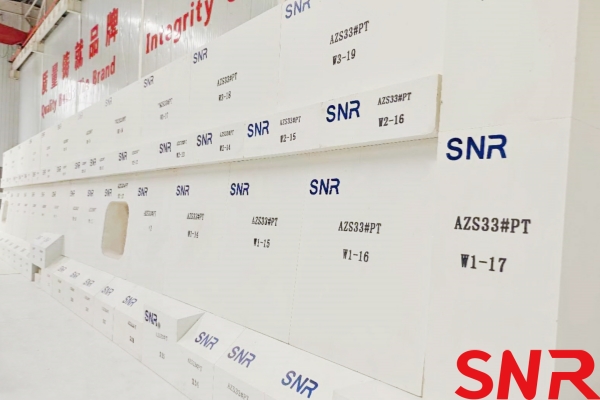

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for about 25 years. We use high-quality raw materials and advanced fusion technology to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

If you have any needs, you can contact me at any time.

Web:www.snr-azs.com

Web:www.snr-azs.com

Email:wendy@snrefractory.com

Email:wendy@snrefractory.com