Fused cast AZS refractory blocks are key construction materials for glass furnaces, with high erosion resistance and low thermal conductivity being the focus of material development. This paper adopts a layered image segmentation method to conduct quantitative analysis of the phase composition of fused cast AZS refractory blocks, combined with glass liquid erosion resistance tests and material thermal conductivity tests, to study the relationship between the phase composition of fused cast AZS refractory blocks and their resistance to glass liquid erosion as well as thermal conductivity.

The results show that by increasing the eutectic content of the material and refining the eutectic grains, the phase composition structure of fused cast AZS refractory blocks can be improved, which helps to enhance the erosion resistance of fused cast AZS refractory blocks against glass liquid and reduce the thermal conductivity of fused cast AZS refractory blocks. This is of great significance for the development and production of fused cast AZS refractory blocks with low thermal conductivity and high erosion resistance, thereby improving the safe operation of glass furnaces and the effects of thermal insulation and energy saving.

1. Introduction

In recent years, with the rapid development of the glass industry, the optimization of glass furnace structures, innovation in glass melting process technologies, and improvement of product quality, especially under the "dual carbon" background, the demand for green, low-carbon, energy-saving and emission reduction in the glass industry has been increasing, placing higher requirements on glass furnace refractory materials. Fused cast AZS refractory blocks must possess both excellent erosion resistance and low thermal conductivity to meet the design requirements of modern glass furnaces for long service life and reduced heat loss.

Fused cast Al2O3-ZrO2-SiO2 (i.e., fused cast AZS refractory blocks, also known as fused cast zirconia-corundum blocks) refractory materials are produced by melting raw materials such as industrial alumina, zircon sand, desilicated zirconia and soda ash in an electric arc glass furnace, then casting into sand molds for solidification, followed by cooling and annealing to obtain a dense shaped refractory material. Fused-cast AZS refractory blocks are divided into three types based on their zirconium content: AZS33 (zirconium content ≥32.5), AZS36 (zirconium content ≥36), and AZS41 (zirconium content ≥41). The products feature high refractoriness, good durability and thermal shock resistance at high temperatures, low porosity (≤1.5%), and strong resistance to glass liquid erosion. They are widely used in various parts of glass furnaces including sidewalls, tank bottoms and breast walls, burner ports, burner skew arches and feeder channels, as well as regenerator side walls.

Although during the casting process of fused cast AZS refractory blocks, different cooling rates at different parts of the product lead to different crystal morphologies. However, unlike ordinary bonded refractory materials which are typical heterogeneous materials usually composed of microstructurally uneven particles, matrices and pores, the microstructure of fused cast AZS refractory blocks is relatively uniform, consisting of intergrown crystals, a small amount of glass phase and pores. For bonded refractory materials, the pores form a continuous phase, and the thermal conductivity of the material is largely affected by the pores. The thermal conductivity of bonded refractory materials can be reduced by appropriately increasing the porosity of the material. But for fused cast AZS refractory blocks, since they are usually used in the innermost layer of glass furnace linings, their long-term erosion resistance needs to be good, with low apparent porosity. Moreover, the pores in fused cast AZS materials are mostly isolated, closed round pores that are not connected to form continuous pores, making it obviously impossible to form open pores to reduce the thermal conductivity of the material by increasing porosity.

The thermal conductivity and corrosion resistance of fused cast AZS refractory blocks mainly depend on their phase structure. However, the relationship between the thermal conductivity and corrosion rate of fused cast AZS refractory blocks based on phase structure is still unclear. This paper aims to quantitatively analyze the phase composition of materials, conduct tests on material thermal conductivity and erosion resistance, and explore the relationship between the phase composition of fused cast AZS refractory blocks and these two important physical properties, providing theoretical and technical foundations for the development of fused cast AZS refractory blocks with low thermal conductivity and high corrosion resistance.

2. Experimental

Industrial alumina powder with w(Al2O3)≥98.5%, zircon sand with w(ZrO2)>65.5%, desilicated zirconia with w(ZrO2)>85.0% were used as raw materials, with w(Na2CO3)≥99.0% soda ash as flux. After uniform mixing according to certain batching compositions, the materials were added to an electric arc glass furnace in batches, melted at temperatures above 1800°C and then cast into molds. The castings underwent condensation, annealing, cutting, grinding and pre-assembly, and were then melted using both conventional melting methods and computer program-controlled forced rapid melting methods to produce fused cast AZS refractory products.

Then, according to JC/T 493-2015 standard, symmetrical sampling was conducted to prepare erosion resistance test specimens of fused cast AZS refractory blocks, with specimen dimensions of 10 mm × 10 mm × 70 mm, 4 pieces per group. According to the industry standard JC/T 806-2013 "Test method for static corrosion resistance of refractory materials for glass melting glass furnaces against glass liquid", erosion resistance tests were conducted on the specimens in soda-lime glass melt at 1500°C × 36 h. The composition of the experimental soda-lime glass is shown in Table 1. A 25× measuring microscope was used to observe and measure the erosion amount at the glass liquid interface of the specimens, and the corrosion rate of the glass melt was calculated.

|

Table 1. Chemical composition of experimental glass / w (mass fraction) |

||||||

|

Ordinary soda-lime glass |

SiO2 |

Al2O3 |

Na2O |

MgO |

CaO |

K2O |

|

Chemical composition/w |

72.2 |

1.5 |

14.3 |

3.9 |

7.8 |

0.3 |

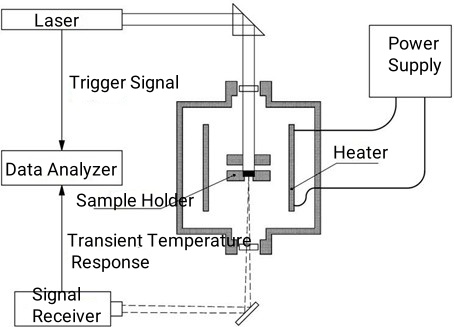

Diamond grinding discs, Auto POL GP-2A automatic polishing machines, special polishing cloths and polycrystalline diamond suspensions were used to grind and polish fused cast AZS refractory blocks microstructural analysis specimens. OM and SEM were used for observation, analysis and photography. The micrographs were imported into specialized software for quantitative analysis of material phase composition. According to ISO 18755:2022 standard, samples with thickness non-uniformity < 1%, diameter or side length between 5 mm and 15 mm (circular or rectangular), and thickness between 0.5 mm and 5 mm were prepared to ensure that the half-rise time (t1/2) value of laser beam heating the sample was more than five times the laser pulse width. The laser flash method was used to determine the thermal diffusivity of fused cast AZS refractory blocks samples. The test device for material thermal diffusivity is shown in Figure 1.

Figure 1. Schematic diagram of thermal diffusivity testing equipment

After measuring the thermal diffusivity of fused cast AZS refractory blocks, the thermal conductivity of fused cast AZS refractory blocks was calculated according to Equation 1.

λ = α·c·ρ (1)

In Equation (1),

Ø λ: thermal conductivity;

Ø α: thermal diffusivity;

Ø c: specific heat capacity;

Ø ρ: bulk density.

In actual testing, the measured value of thermal diffusivity of fused cast AZS refractory blocks is directly read by the instrument. After inputting the previously measured specific heat capacity c and bulk density ρ of fused cast AZS refractory blocks, the measured value of thermal conductivity of fused cast AZS refractory blocks can then be directly read by the instrument.

3. Results and Discussion

3.1 Phase Composition of Materials

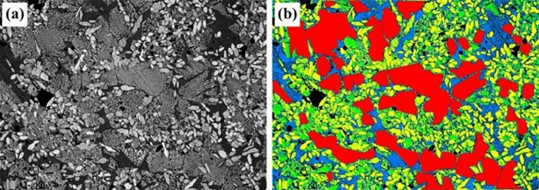

Image analysis method was used to quantitatively analyze the phase composition in the microstructure of polished fused cast AZS refractory blocks specimens. The microstructure photos of the materials were imported into specialized software. Based on the gray-scale differences of each phase in the microstructure, the specialized software fitted the contours of the phases according to the iterative principle, and then sequentially segmented and labeled the images in the microstructure photos, as shown in Figure 2.

Figure 2(a) is the initial optical micrograph of fused cast AZS refractory blocks sample, in which the white phase is baddeleyite, the gray-white alternating phase is Al2O3-ZrO2 eutectic, the light gray phase is corundum, the dark gray phase is glass phase, and the black phase is pores. Figure 2(b) is the microstructure photo after labeling by the specialized software, in which the red phase is Al2O3-ZrO2 eutectic, the yellow phase is baddeleyite, the green phase is corundum, the blue phase is glass phase, and the black phase is pores. Subsequently, the specialized software obtained the relative content of each phase according to the area percentage of each phase after labeling. To ensure the accuracy of quantitative analysis data, each sampling area was divided into two layers, and three microstructure photos at different locations in the same layer were analyzed to obtain the relative content of each phase respectively. The results were then averaged to represent the actual phase composition of fused cast AZS refractory blocks in that sampling area, expressed as volume fraction. Since the porosity of fused cast AZS refractory blocks is very small, after removing pores for normalized statistics, the phase composition of fused cast AZS refractory blocks is shown in Table 2.

Figure 2. Microstructure photos of fused cast AZS refractory blocks and their image segmentation and labeling

(a) Initial microstructure photo (×50);

(b) Labeled microstructure photo (×50)

|

Table 2. Typical phase composition of fused cast AZS refractory blocks |

|||||

|

Sample |

Product Crystallization Zone |

Phase Composition (volume fraction)/% |

|||

|

Al2O3-ZrO2 Eutectic |

Corundum |

Baddeleyite |

Glass Phase |

||

|

33# AZS |

Fine crystal zone |

60.8 |

1.8 |

15.5 |

21.9 |

|

Medium crystal zone |

52.7 |

2.5 |

17.8 |

27.0 |

|

|

Coarse crystal zone |

59.3 |

4.2 |

6.1 |

30.4 |

|

|

36# AZS |

Fine crystal zone |

57.5 |

4.6 |

18.2 |

19.7 |

|

Medium crystal zone |

59.6 |

6.2 |

12.9 |

21.3 |

|

|

Coarse crystal zone |

63.5 |

5.5 |

6.2 |

24.8 |

|

|

41# AZS |

Fine crystal zone |

67.7 |

3.8 |

12.5 |

16.0 |

|

Medium crystal zone |

68.1 |

4.4 |

10.2 |

17.3 |

|

|

Coarse crystal zone |

70.5 |

2.1 |

4.3 |

23.1 |

|

3.2 Effect of Forced Rapid Melting Process on Material Microstructure

During the smelting process of electric arc glass furnace, the power load of three-phase AC electric arc glass furnace is unstable and asymmetric. Due to unstable arc combustion, arc breaking, short circuit and material pile movement often occur, resulting in serious load asymmetry; during the operation of electric arc glass furnace, other human factors such as improper adjustment of electrode regulator will also cause three-phase current asymmetry of electric arc glass furnace. Therefore, using conventional system control methods, the melting of fused cast AZS refractory blocks will be frequently disturbed by three-phase current, voltage and impedance, and the corresponding melting process is called conventional melting process.

Based on adaptive control theory, aiming at the characteristics of fused cast AZS refractory blocks smelting production such as nonlinear time-varying, strong coupling, large lag, and strong random interference in working environment, a highly reliable programmable control system for electric arc glass furnace was adopted for melting fused cast AZS refractory blocks. This system can adapt to changes in glass furnace conditions in real time, automatically adjust electrode controller parameters, which is conducive to ensuring stable electrode adjustment and meeting the requirements of electric arc glass furnace temperature and three-phase current balance. At the same time, it increases the active power of the melting process and reduces energy consumption. The melting process of fused cast AZS refractory blocks production using the new electric arc glass furnace program control system is called forced rapid melting process. The new process solves the problems of large chemical composition fluctuation and unstable product quality of fused cast AZS refractory blocks produced by conventional melting process. The effect of different melting processes on the phase composition of fused cast AZS refractory blocks is shown in Table 3.

|

Table 3. Effect of different melting processes and formulations on phase composition of fused cast 33# AZS blocks |

||||||

|

Sample No. |

Phase Composition / vol.% |

Formulation Composition |

Melting Process |

|||

|

Corundum Phase |

Baddeleyite |

Eutectic |

Glass Phase |

|||

|

1 |

2.1 |

15.6 |

61.1 |

21.2 |

Formulation A |

Forced Rapid Melting |

|

2 |

2.8 |

18.0 |

53.2 |

26.0 |

Formulation B |

Conventional Melting |

|

3 |

7.1 |

14.5 |

49.3 |

29.1 |

Formulation A |

Conventional Melting |

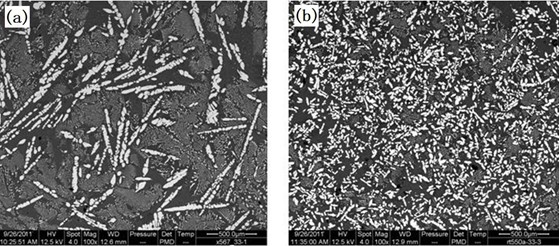

Figure 3 shows the scanning electron microscope photos of the microstructure of fused cast AZS products prepared by different melting processes. It can be seen that the products prepared by computer program-controlled forced rapid melting have more uniform microstructure, and the overall distribution of crystal phases is also more uniform. In addition, the content of Al2O3-ZrO2 eutectic is increased and refined, mainly in the form of sheet columns, which can improve the phase composition and microstructure of the material. Due to rapid melting, the thermal uniformity of the melt in the molten tank increases, and the time from molten state to solidification is shortened. This means that the crystal growth time is shortened, so the growth of grains is limited, showing a further refinement trend. The higher solidification formation rate also makes it easier to form eutectic structures with orderly crystal arrangement and uniform phase distribution.

Figure 3. Microstructure of fused cast Fused cast AZS refractory blocks prepared by different melting processes

(a) Conventional melting;

(b) Forced rapid melting

3.3 Effect of Material Phase Composition on Its Thermophysical Properties

According to the quantitative analysis of phase composition of fused cast AZS refractory blocks, glass liquid erosion resistance tests and material thermal conductivity test results, statistical analysis was conducted on the influence of the main phase in fused cast AZS refractory blocks microstructure, namely Al2O3-ZrO2 eutectic, on the erosion resistance and thermal conductivity of the material. The mathematical relationships between material thermal conductivity, erosion resistance and the content and particle size of the main crystal phase were obtained as follows:

λ = -0.05364e + 0.01474de + 6.4944, R2 = 0.98 (2)

ε = -0.04191e + 0.009717de + 3.8288, R2 = 0.81 (3)

In Equations 2 and 3, λ is the thermal conductivity of fused cast AZS refractory blocks at 1000°C, in W·(m·K)-1; ε is the corrosion rate of the material in soda-lime glass liquid, in mm/24 h; e is the content of Al2O3-ZrO2 eutectic in the material, in %; de is the average particle size of Al2O3-ZrO2 eutectic, in μm. The Pearson coefficient between λ and ε is 0.85, indicating a highly positive correlation between them.

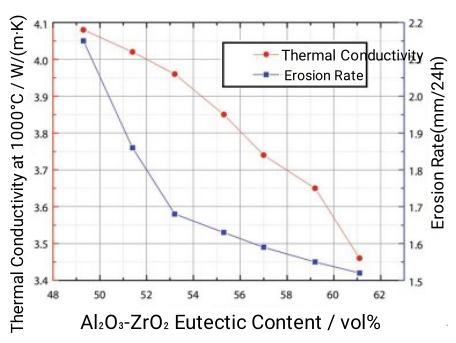

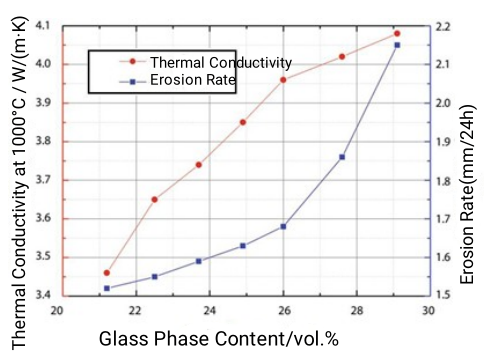

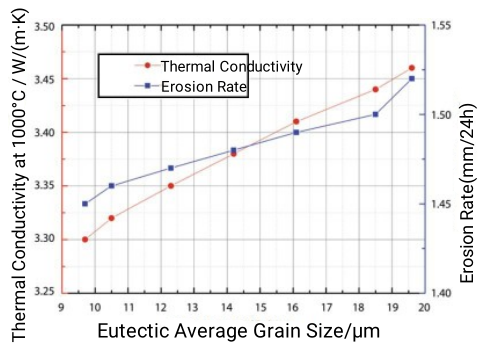

Figures 4, 5 and 6 respectively show the relationships between the content of Al2O3-ZrO2 eutectic, glass phase content and average eutectic particle size in fused cast AZS refractory blocks and the corrosion resistance and thermal conductivity of the materials. From Figures 4, 5 and 6, it can be seen that as the content of Al2O3-ZrO2 eutectic in the material increases, and the grains are refined and the glass phase content decreases, the corrosion rate of glass melt and the thermal conductivity of the material decrease.

Figure 4. Relationship between glass erosion resistance, thermal conductivity and eutectic content in fused cast AZS refractory block samples

Figure 5. Relationship between glass erosion resistance, thermal conductivity and glass phase content in fused cast AZS refractory block samples

Figure 6. Relationship between glass erosion resistance, thermal conductivity and average eutectic particle size in fused cast AZS refractory block samples

The microstructure of fused cast AZS refractory blocks is mainly composed of Al2O3-ZrO2 eutectic, glass phase, baddeleyite and corundum single crystals. Their chemical stability and corrosion resistance are in the order of zirconia, corundum and glass phase. The glass phase, which is most easily corroded by molten glass, is mainly composed of silica. At high temperatures, as the glass phase filling between the crystal skeleton structures is corroded and replaced, the density of the internal structure of fused cast AZS refractory blocks decreases, providing channels for the penetration and diffusion of low-viscosity molten glass liquid and increasing damage to the material. Therefore, relatively reducing the glass phase content of fused cast AZS refractory blocks and increasing the exudation temperature of glass phase are beneficial to improving the corrosion resistance of materials.

The baddeleyite inside fused cast AZS refractory blocks exists in three forms: the first is scattered baddeleyite, mainly existing in the form of bead-like and dendritic aggregates; the second is wrapped by corundum crystals in eutectic; the third is distributed as fine microcrystals in glass phase. They mostly exist in the first two forms (see Tables 2-3). Eutectic solidification refers to the process in which when the temperature of liquid melt is lower than a certain temperature (eutectic temperature), two components of the melt simultaneously precipitate to form eutectic. Therefore, eutectic solidification occurs during the melting and cooling process of alumina and zirconia. Since the corundum at the edge of Al2O3-ZrO2 eutectic dissolves first, and the ZrO2 segregation phase is only a few micrometers or smaller, it will promote dissolution and form a dense protective layer on the corundum surface after dissolution to prevent further internal corrosion. Therefore, increasing the content of Al2O3-ZrO2 eutectic through process improvement is an effective way to improve the erosion resistance of fused cast AZS refractory blocks against glass liquid.

The thermal conductivity of refractory materials λ = q/(-dT/dx), where q refers to heat flux density, and dT/dx refers to temperature gradient. Generally, crystals have negative thermal conductivity temperature coefficients, i.e., dλ/dT < 0; glassy and amorphous substances have positive thermal conductivity temperature coefficients, i.e., dλ/dT > 0. Although glass phase or pores are beneficial to reduce the thermal conductivity of refractory materials, limited by the high erosion resistance requirements of fused cast refractory materials, the thermal conductivity of fused cast AZS refractory blocks can only be reduced by starting from their phase composition and organizational structure. Research has shown that the more complex the material‘s crystal structure, the more solid solutions the chemical components form, and the more pronounced the reduction in the material‘s thermal conductivity. The results in Table 4 demonstrate that by reducing the amount of scattered baddeleyite in the material structure, the formation of eutectics between baddeleyite and corundum is promoted, significantly increasing the eutectic content and the complexity of the material‘s crystal structure. This can reduce the thermal conductivity of fused cast AZS refractory blocks while maintaining their corrosion resistance.

|

Table 4. Relationship between phase occurrence in fused cast materials and their thermal conductivity and erosion resistance |

||||||

|

Sample No. * |

Phase Composition / vol.% |

Erosion Resistance / (mm/24 h) |

Thermal Conductivity at 1000°C / W·(m·k)-1 |

|||

|

Corundum Phase |

Baddeleyite |

Eutectic |

Glass Phase |

At glass liquid interface |

||

|

1 |

2.1 |

15.6 |

61.1 |

21.2 |

1.45 |

3.30 |

|

2 |

2.8 |

18.0 |

53.2 |

26 |

1.68 |

3.96 |

|

3 |

7.1 |

14.5 |

49.3 |

29.1 |

2.15 |

4.08 |

*Sample 1 is new process product, Samples 2 and 3 are conventional process products

On the other hand, since heat transfer is carried out through lattice vibration, after the grains are refined, the number of grain boundaries inside them increases, and the increase in eutectic content makes the internal structure more complex, which leads to increased phonon scattering and reduced mean free path. Thus, the thermal conductivity of fused cast AZS refractory blocks is significantly reduced (see Table 4). The application of fused cast AZS refractory blocks with low thermal conductivity can prevent and eliminate the phenomenon of large-scale degeneration caused by the low refractoriness of external lining lightweight insulation bricks that are difficult to resist high temperature effects, thereby avoiding the failure of lightweight materials, preserving the insulation performance of external lining layers, improving insulation effects and reducing heat loss of masonry structures. This is of great significance for extending the service life of glass furnaces, effectively improving the energy-saving effect of glass furnace insulation and reducing production energy consumption.

4. Performance Optimization and Future Development Trends of Fused Cast AZS Refractories in Industrial Applications

4.1 Performance Optimization in Industrial Applications

Fused cast AZS refractories are widely used in critical parts of glass furnaces due to their excellent corrosion resistance and low thermal conductivity. However, in practical industrial applications, material performance is also influenced by various external factors. For example:

► Long-Term Effects of Chemical Corrosion: Although fused cast AZS materials exhibit high resistance to soda-lime glass melt, the glass phase may still be gradually eroded over prolonged use. Therefore, further reducing the glass phase content or improving its chemical stability is a key focus for future research.

► Mechanical Wear and Impact: During furnace operation, the material may be subjected to mechanical wear or glass melt impact. Increasing the hardness and density of eutectic phases can effectively improve the material‘s wear resistance and impact resistance.

4.2 Further Optimization of Material Preparation Processes

In addition to the forced rapid melting process, other preparation techniques can be explored to enhance the performance of fused cast AZS materials:

► Precise Control of Cooling Rates: Adjusting the cooling rate during the annealing process can further refine grains and optimize phase distribution. Rapid cooling may inhibit grain growth, resulting in a more uniform microstructure.

► Application of New Melting Technologies: Techniques such as plasma melting or microwave melting may achieve more efficient melting and more homogeneous melt composition distribution, thereby enhancing the overall performance of the material.

4.3 Environmental and Economic Benefits Analysis

Under the "dual carbon" policy, the low thermal conductivity of fused cast AZS refractories not only contributes to energy savings and emission reductions but also reduces production costs. Specific benefits include:

► Extended Furnace Lifespan: Highly corrosion-resistant materials can significantly prolong furnace service life, reduce the frequency of shutdowns for maintenance, and thereby lower maintenance costs and production losses.

► Resource Utilization Efficiency: Optimizing formulations and processes can reduce reliance on high-purity raw materials, lower production costs, and improve material recycling rates.

4.4 Future Research Directions and Challenges

Although significant progress has been made in fused cast AZS refractories, several challenges remain:

► Multifunctional Development: Future fused cast AZS materials may need to incorporate additional functionalities, such as self-healing capabilities or intelligent temperature control, to adapt to more complex industrial environments.

► Green Preparation Technologies: Exploring more environmentally friendly preparation processes to reduce carbon emissions and energy consumption during production is an important direction for future research.

5. Conclusion

The performance optimization of fused cast AZS refractory block is a multidisciplinary and systematic engineering challenge, with its core lying in the synergistic enhancement of material properties through phase composition and preparation process optimization. This study established quantitative relationships between Al₂O₃-ZrO₂ eutectic content, glass phase content, grain size, and material performance through quantitative phase analysis, thermal conductivity testing, and glass melt corrosion resistance experiments. Experimental results demonstrated that increasing the Al₂O₃-ZrO₂ eutectic content to over 60%, reducing the glass phase content to below 20%, and refining grains to the micrometer level can simultaneously lower the material‘s thermal conductivity (reaching 3.30 W·(m·k)^-1 at 1000°C) and corrosion rate (1.45 mm/24h). Notably, the computer-controlled forced rapid melting process, by precisely regulating the temperature field and solidification rate during melting, not only increased eutectic content (8–15% higher than conventional processes) and refined grains (30–50% reduction in size) but also significantly improved microstructure uniformity. These findings provide important theoretical and technical guidance for developing new fused cast AZS materials with both low thermal conductivity (<3.5 W·(m·k)^-1) and high corrosion resistance (corrosion rate <1.5 mm/24h), offering substantial engineering value for energy savings and extended service life in glass furnaces. Future research could further explore new methods such as additive modification and multi-scale structural regulation to continuously enhance material performance and expand its industrial applications.

Henan SNR Refractory Co., Ltd. is dedicated to the manufacture, research and development of fused cast AZS refractory blocks and bonded refractory materials for the glass industry. Meanwhile, SNR can provide total solutions and services for glass furnace design, glass furnace construction, renovation, and upgrading. Please contact me if you have any requirements.

CONTACT: zoe@snrefractory.com/ WhatsApp:+86 18172389584