Ensuring glass melting quality is a core step in glass production, directly determining the performance of subsequent forming, annealing, and final products (such as transparency, strength, and flatness). Its core goal is to achieve complete melting of raw materials, thorough removal of bubbles, uniform mixing of components, and freedom from defects like stones. Specifically, this can be systematically controlled through four dimensions: raw material control, furnace design and maintenance, process parameter optimization, and process monitoring. Below is a detailed plan:

Ⅰ. Raw Material Phase: Controlling "Inherent Quality" from the Source

II. Furnace Design and Maintenance: Creating a Stable "Melting Environment"

III. Process Parameter Optimization: Precisely Controlling the "Melting Process"

IV. Process Monitoring and Defect Management: Timely Detection and Problem-Solving

I. Raw Material Phase: Controlling "Inherent Quality" from the Source

Raw materials are the foundation of glass melting, and their purity, proportioning, particle size, and uniformity directly affect melting efficiency and glass melt quality. The following five aspects require key control:

1. Raw Material Purity and Impurity Management

Defects in glass such as stones (unmelted raw material particles, refractory debris) and streaks (component inhomogeneity) mostly originate from raw material impurities. Raw materials must be strictly screened:

- Main raw materials : Silica sand (SiO₂) should have controlled iron content (Fe₂O₃ < 0.1% to prevent glass from turning green) and alumina content (Al₂O₃ < 2% as excessive amounts increase melting temperature); soda ash (Na₂CO₃) needs to control sodium chloride (NaCl < 0.5%) and iron impurities; limestone (CaCO₃) should avoid excessive magnesium and sulfur impurities.

- Impurity removal: Magnetic separation (to remove iron filings), screening (to remove large gravel particles), and water washing (to remove clay and dust) are used to reduce physical impurities in raw materials; hygroscopic raw materials (such as soda ash and Glauber‘s salt) are dried to prevent caking from affecting mixing uniformity.

2. Precise Batching: Ensuring Composition Meets Design Requirements

Glass composition (e.g., soda-lime-silica glass, borosilicate glass) must be precisely controlled through batching; deviations can lead to fluctuations in melting temperature and substandard performance:

- Batching accuracy: Electronic scales (accuracy ±0.1%) or loss-in-weight feeders are used to strictly control the weighing error of each raw material; trace additives (such as fining agents and colorants) need to be weighed separately and accurately to avoid affecting fining efficiency or color stability due to dosage deviations.

- Batching calculation: Based on glass composition design (e.g., soda-lime-silica glass typically contains 70-73% SiO₂, 13-16% Na₂O, and 8-10% CaO), the batching ratio is dynamically adjusted according to the actual composition of raw materials (e.g., the actual SiO₂ content in silica sand) to avoid disconnect between "theoretical batching" and "actual raw materials".

3. Optimization of Raw Material Particle Size and Gradation

Raw material particle size directly affects melting rate: excessively large particles tend to form unmelted stones, while excessively small particles are prone to fly away (causing raw material loss) and "bridging" in the furnace (raw material accumulation and non-flowing, leading to local overheating).

- Reasonable particle size range: Silica sand particle size is controlled at 0.15-0.8mm (fine powder <0.15mm accounts for <10%, coarse particles >0.8mm account for <5%); soda ash and limestone particle sizes are controlled at 0.1-0.5mm to ensure matching with silica sand particle size.

- Particle size uniformity: Screening and classification are used to avoid excessive particle size differences in the same raw material, ensuring synchronous melting of raw materials in the furnace.

4. Uniform Mixing: Avoiding "Local Component Inhomogeneity"

Inhomogeneous mixing of raw materials can lead to "streaks" (local component deviations) in the glass melt, requiring efficient mixing equipment to achieve uniformity:

- Mixing equipment: Twin-shaft paddle mixers (mixing time 5-8 minutes) or drum mixers are used to ensure dry material mixing uniformity ≥95%; secondary separation after mixing (such as fine powder sedimentation during transportation) should be avoided, and "wet mixing" (adding 2-3% water) or binders can be used to reduce particle classification.

- Batch stability: After mixing raw materials in the same batch, samples should be taken to test composition to ensure component fluctuation between different batches is <0.5%.

II. Furnace Design and Maintenance: Creating a Stable "Melting Environment"

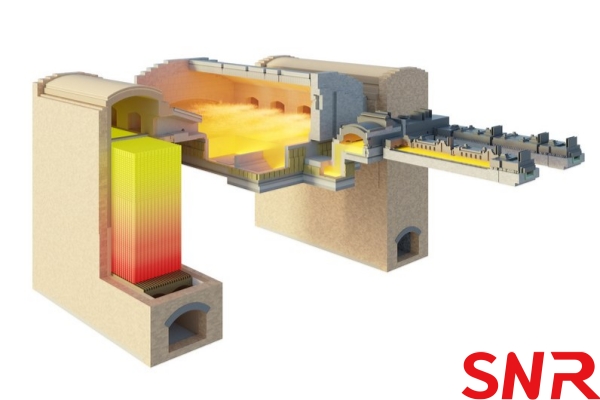

The glass melting furnace is the core equipment for raw material melting, fining, and homogenization. Its structural design, refractory material selection, and daily maintenance directly affect melting stability and glass melt quality.

1. Furnace Structure Optimization: Matching Melting Process Requirements

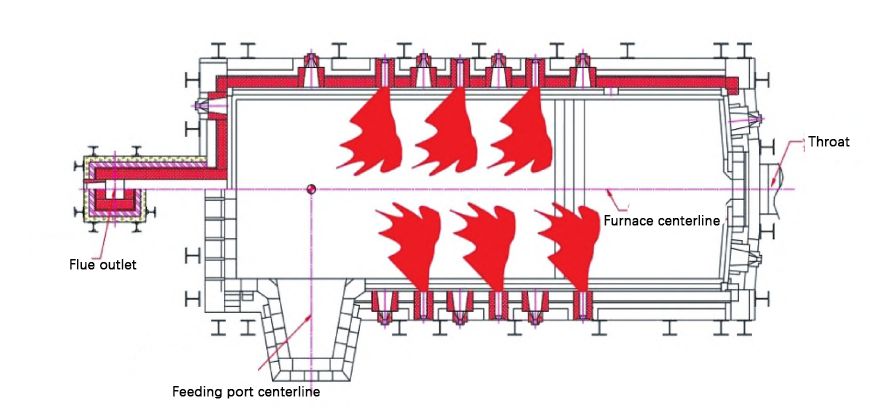

Different glass types (e.g., flat glass, container glass, optical glass) require corresponding furnace structures, with the core goal of achieving "reasonable temperature distribution and orderly material flow":

- Melting zone: It should have sufficient area (melting area matches production capacity; e.g., flat glass melting furnaces are usually designed at 1.2-1.5 tons/㎡·day) and depth (1.2-1.8m) to ensure sufficient melting time for raw materials; a "deep pool melting" design is adopted to promote homogenization through convective circulation of the glass melt.

- Fining zone: Located behind the melting zone, it needs to "expand diameter" (cross-section expansion, glass melt flow rate reduced to 0.5-1m/h) and "increase temperature" (temperature 50-100℃ higher than the melting zone, usually 1550-1600℃) to allow bubbles to fully float and be removed; some high-grade glass furnaces are equipped with "bubbling devices" (injecting nitrogen/compressed air into the bottom of the glass melt) to break the surface tension of bubbles and accelerate fining.

- Homogenization zone: Forced glass melt mixing is achieved through "stirring devices" (e.g., platinum-rhodium alloy stirring paddles) or "baffle + throat" design to eliminate component and temperature gradients; the homogenization zone temperature must be stable (fluctuation within ±5℃) to avoid secondary crystallization caused by local cooling.

2. Refractory Material Selection: Reducing "In-furnace Contamination"

Refractory materials are the "lining" of the furnace, and their erosion and falling off are one of the main sources of "stones" in glass. Suitable materials should be selected according to the working conditions of different parts of the furnace:

- Melting zone pool wall: In contact with high-temperature glass melt and flame, corrosion-resistant fused zirconia-corundum bricks (ZrO₂ content 33-41%) are used to prevent erosion by the glass melt and stone formation.

- Fining zone: With the highest temperature and strong glass melt fluidity, premium fused zirconia-corundum bricks or fused α-β corundum bricks are used to improve high-temperature resistance and erosion resistance.

- Furnace roof: Subject to high-temperature flame radiation, lightweight high-alumina bricks or silica bricks (silica bricks can withstand temperatures up to 1650℃ but should avoid contact with alkaline glass melt) are used to reduce the risk of roof collapse.

3. Daily Furnace Maintenance: Extending Service Life + Stabilizing Working Conditions

Regular maintenance of the furnace during operation is required to avoid melting quality fluctuations caused by equipment aging:

- Regular inspection: Daily observation of whether the pool wall and furnace roof have cracks, erosion, or brick falling off; timely repair with refractory mortar if problems are found; weekly detection of refractory material erosion rate; shutdown and replacement when erosion depth exceeds 1/3 of the design value.

- Furnace sealing: Ensure good sealing of furnace doors, observation holes, flues, and other parts to prevent cold air leakage (causing local temperature reduction and unmelted material formation) or excessive heat loss (increasing energy consumption).

- Regenerator maintenance: Regenerators (recovering flue gas heat to preheat combustion air) need to clean lattice brick dust regularly (once every 3-6 months) to avoid blockage affecting heat exchange efficiency and causing unstable melting temperature.

III. Process Parameter Optimization: Precisely Controlling the "Melting Process"

The core parameters of the melting process (temperature, atmosphere, pressure, time) need to be controlled synergistically to ensure the stability of the entire "melting-fining-homogenization" stage of raw materials.

1. Temperature Control: The Core of the Core

Temperature is the driving force of melting, requiring "segmented precise temperature control" to avoid local overheating or insufficient temperature:

- Melting zone temperature: Controlled at 1450-1550℃ to ensure complete melting of raw materials (silica sand has a melting point of approximately 1710℃, but the melting temperature of mixed raw materials can be reduced to around 1400℃ with flux such as soda ash); the flame length and angle of burners are adjusted to achieve uniform temperature distribution in the melting zone (transverse temperature difference <20℃, longitudinal temperature difference <50℃).

- Fining zone temperature: 50-100℃ higher than the melting zone (1550-1600℃); at this time, the glass melt viscosity decreases (<10 poise), allowing bubbles to float easily; excessive temperature can cause excessive erosion of refractory materials, requiring precise control.

- Homogenization zone temperature: Controlled at 1450-1500℃, slightly lower than the fining zone, to avoid excessive volatilization of the glass melt while maintaining good fluidity for homogenization.

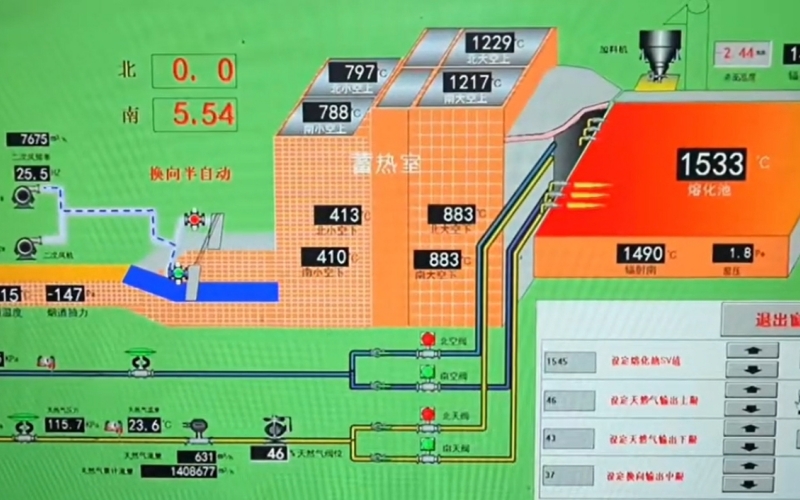

- Temperature control methods: Thermocouples (inserted into the glass melt or furnace space) are used for real-time temperature monitoring; automatic temperature control is achieved by adjusting the ratio of fuel (natural gas, heavy oil) and combustion air (air-fuel ratio usually 1.05-1.15 to ensure complete combustion), with temperature fluctuation controlled within ±5℃.

2. In-furnace Atmosphere Control: Avoiding "Redox Defects"

The in-furnace atmosphere (oxidizing/reducing) affects glass color, fining efficiency, and refractory service life:

- Oxidizing atmosphere: Most glasses (e.g., soda-lime-silica glass) need to be melted in an oxidizing atmosphere (excess air coefficient 1.1-1.2), which can promote the decomposition of sulfide fining agents (such as Glauber‘s salt Na₂SO₄) into SO₂ to help remove bubbles; meanwhile, it prevents iron impurities from being reduced to Fe²+ (causing glass to turn green).

- Reducing atmosphere: Only used for special glasses (e.g., selenium-containing brown glass), achieved by reducing the air-fuel ratio (0.9-1.0), but strict control is required to avoid excessive reduction leading to ferrous sulfide stones in the glass melt.

- Atmosphere uniformity: Reasonable arrangement of burners (e.g., side-fired burners with spacing 1.5-2m) and control of combustion air distribution ensure uniform in-furnace atmosphere and avoid local reduction or oxidation.

3. Furnace Pressure Control: Stabilizing "Airflow and Temperature"

In-furnace pressure directly affects flame shape and temperature distribution, requiring maintenance of slight positive pressure:

- Pressure range: The melting zone furnace pressure is controlled at 0-5Pa (slight positive pressure) to prevent cold air leakage from furnace doors and observation holes (causing local temperature reduction); the fining zone pressure is slightly higher than the melting zone (5-10Pa) to promote flue gas flow to the melting zone and recover heat.

- Pressure control methods: Real-time control of in-furnace pressure is achieved by adjusting the opening of the flue damper, with pressure fluctuation controlled within ±1Pa.

4. Melting Time Control: Ensuring "Sufficient Reaction"

Raw materials need to stay in the furnace long enough to ensure complete melting, fining, and homogenization:

- Total residence time: Usually 8-16 hours (flat glass furnaces have a longer residence time, approximately 12-16 hours; container glass is about 8-12 hours), depending on the glass type and furnace production capacity.

- Segmented time: The melting stage (raw material → molten glass) accounts for 30-40% of the total time, the fining stage (bubble removal) accounts for 20-30%, and the homogenization stage (component mixing) accounts for 30-40%.

- Control methods: The residence time is controlled by adjusting the flow rate of the glass melt (changing the throat opening) or the furnace depth; insufficient residence time caused by excessive production capacity (overload operation) should be avoided to prevent defects such as unmelted material and bubbles.

IV. Process Monitoring and Defect Management: Timely Detection and Problem-Solving

Even if the first three links are well controlled, real-time monitoring and defect detection are still needed to adjust process parameters in time and prevent unqualified glass melt from entering subsequent processes.

1. Online Monitoring: Real-time Mastery of Melting Status

- Glass melt temperature monitoring: Insertion thermocouples (directly contacting the glass melt) or infrared thermometers (non-contact) are used to real-time monitor the temperature of the melting zone, fining zone, and homogenization zone; data is transmitted to the central control system, and alarms and fuel supply adjustments are automatically triggered when abnormalities occur.

- Glass melt viscosity monitoring: A "viscometer" (e.g., rotational viscometer) is used to real-time measure glass melt viscosity (viscosity directly reflects temperature and component status), and temperature or batching is adjusted in time when viscosity is abnormal.

- Bubble and stone monitoring: An "online detector" (e.g., laser scanner, image recognition system) is installed at the outlet of the homogenization zone to real-time capture the glass melt flow, automatically identify defects such as bubbles and stones, and immediately shut down for adjustment when defects exceed standards.

2. Offline Detection: Laboratory Quality Verification

- Sampling and testing: Samples are taken from the glass melt flow every hour, and the following indicators are tested after sample preparation:

- Component analysis: X-ray fluorescence spectroscopy (XRF) is used to detect main components such as SiO₂, Na₂O, and CaO to ensure compliance with design requirements.

- Defect detection: Samples are ground into slices and observed under a microscope to count the number and size of stones and bubbles (e.g., flat glass requires <1 stone per square meter, and bubble diameter <0.1mm).

- Performance testing: Glass refractive index, density, thermal expansion coefficient, etc., are tested to verify compliance with product standards.

- Raw material re-inspection: After each batch of raw materials enters the factory, samples are taken to test purity, particle size, and composition; unqualified raw materials are prohibited from being used.

3. Defect Analysis and Traceability: Targeted Problem-Solving

When quality defects occur, tools such as "fishbone diagrams" should be used to trace the root cause:

- Stones: If they are siliceous stones, it may be due to excessively large raw material particle size or insufficient melting temperature; if they are zirconium stones, it may be due to erosion and falling off of pool wall zirconia-corundum bricks, requiring refractory material

inspection or melting temperature increase.

- Bubbles: If they are small bubbles, it may be due to insufficient fining temperature or insufficient fining agent dosage; if they are large bubbles, it may be due to in-furnace pressure fluctuation or excessive moisture content in raw materials, requiring adjustment of fining temperature or raw material drying process.

- Streaks: May be due to inhomogeneous raw material mixing or insufficient homogenization time, requiring optimization of mixing equipment or extension of homogenization time.

Ensuring glass melting quality is a "systematic project" that requires coordinated efforts from four dimensions: raw materials (source), furnace (carrier), process (process), and monitoring (guarantee). The core is to achieve "complete raw material melting, uniform components, thorough bubble removal, and no refractory contamination". At the same time, a normalized quality traceability mechanism should be established to dynamically optimize parameters based on defect feedback, so as to continuously and stably produce high-quality glass.

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for about 25 years. We use high-quality raw materials and advanced fusion technology to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

If you have any needs, you can contact me at any time.

If you have any needs, you can contact me at any time.

Web: www.snr-azs.com

Email:wendy@snrefractory.com