Fused Cast Alumina-Zirconia-Silica (AZS) Blocks, also referred to as fused cast Al₂O₃-ZrO₂-SiO₂ blocks, are high-grade refractory materials primarily composed of Al₂O₃, ZrO₂, and SiO₂. They are manufactured through electric arc furnace melting and casting processes.

Renowned for their exceptional resistance to high-temperature scouring, corrosion from glass melts, and excellent thermal stability, these blocks are extensively utilized in critical sections of glass melting furnaces, such as the melting zone tank walls, refining zone, and throat.

They serve as fundamental materials for ensuring both glass melting quality and furnace service longevity. The following provides a comprehensive analysis from three perspectives: "Proper Application," "Erosion Mechanisms," and "Protection Measures."

I. Proper Application of Fused Cast AZS Blocks

II. Erosion Mechanisms of Fused Cast AZS Blocks

III. Protection Measures for Fused Cast AZS Blocks

IV. Conclusion

The performance of fused cast AZS blocks is directly correlated with their ZrO₂ content. Products of different grades exhibit significant variation in their suitable application scenarios. To maximize service life, it is imperative to accurately select the appropriate grade based on the specific operating conditions (temperature, glass melt flow rate, and corrosion intensity) of each furnace section and to ensure standardized construction practices.

1. Grade Selection: Matching ZrO₂ Content to Application Sections

Fused cast AZS blocks are typically classified into three primary grades based on ZrO₂ content: 33# (ZrO₂: 33% ±1), 36# (ZrO₂: 36% ±1), and 41# (ZrO₂: 41% ±1). Their performance enhances with increasing ZrO₂ content, and each grade must be precisely matched to its appropriate furnace section.

Fused cast AZS 33# Block: This grade contains approximately 33% ZrO₂. Its key performance characteristics include lower cost, moderate corrosion resistance, and good thermal shock stability. It is suitably applied to the lower-middle sections of the melting zone tank walls (non-hot spot areas), both sides of the charging pool, and the throat tank walls.

Fused cast AZS 36# Block: Containing around 36% ZrO₂, this grade offers superior corrosion resistance compared to the 33# AZS block and possesses a balanced overall performance profile. Its applicable sections include the tank walls within the hot spot area of the melting zone, the lower tank walls of the refining zone, and both sides of the throat inlet.

Fused cast AZS 41# Block: With a ZrO₂ content of roughly 41%, this grade demonstrates optimal performance in resisting glass melt corrosion and high-temperature scouring. However, its thermal shock stability is slightly inferior to the previous two grades. It is primarily used in the tank walls of the high-temperature area within the refining zone, throat linings, forehearth cover blocks, and other furnace sections subjected to the most severe erosion.

Selection Principle: It is crucial to avoid both "over-specification" (e.g., using 41# AZS blocks in non-hot spot areas, leading to unnecessary cost expenditure) and "under-specification" (e.g., using 33# AZS blocks in hot spot areas, resulting in premature erosion).

2. Construction Standards: Ensuring Compatibility Between Blocks and the Glass Furnace

Construction quality directly impacts the performance of AZS blocks. Improper construction can readily lead to block cracking, glass melt penetration, and accelerated erosion.

1. Block Pre-treatment:

Prior to construction, each block must be inspected for appearance. Blocks exhibiting cracks, chipped corners, or blowholes should be rejected. The joint surfaces of the blocks should be ground to ensure a flatness error of ≤ 0.5 mm, guaranteeing tight joints.

2. Masonry Method:

The "wet masonry method" should be employed, using a zirconia-containing refractory mortar (with a ZrO₂ content ≥ 30%) that is compatible with the AZS block composition. The thickness of the mortar joint must be controlled within 1-2 mm, as excessively thick joints can become weak points susceptible to erosion. During masonry, ensure blocks are vertically aligned and level to prevent local stress concentration caused by misalignment.

3. Expansion Joint Provision:

AZS blocks possess a relatively high thermal expansion coefficient (approximately 5.5 × 10⁻⁶/°C between 20°C and 1600°C). Expansion joints of 0.5-1 mm must be reserved between blocks and filled with flexible refractory materials, such as ceramic fiber paper, to prevent block cracking due to compression during heating.

4. Heating and Glass Furnace Baking:

Before furnace commissioning, a slow baking process according to a defined "stepwise heating curve" is essential (typically taking 7-10 days to reach 1000°C from room temperature). This avoids thermal shock cracks caused by excessive temperature differences between the inner and outer parts of the blocks due to overly rapid heating.

3. Operational Control: Avoiding Accelerated Wear from Abnormal Conditions

Temperature Control: The furnace temperature must be strictly maintained within the designed range. Localized overheating (e.g., the refining zone temperature exceeding 1650°C) must be prevented, as high temperatures reduce the strength of AZS blocks and accelerate penetration and erosion by the glass melt.

Glass Melt Flow Rate Control: The throat opening should be adjusted and production capacity managed to prevent excessive glass melt flow rates (e.g., exceeding 1.5 m/h) at sections lined with AZS blocks. This reduces the scouring and wear on the block surfaces caused by high-velocity glass melt.

Atmosphere Control: A proper oxidizing atmosphere should be maintained within the furnace (excess air ratio typically between 1.1 and 1.2). Local reducing atmospheres must be avoided, as they increase the concentration of Fe²⁺ and S²⁻ ions in the glass melt, thereby accelerating the reductive erosion of the ZrO₂ component within the AZS blocks.

II. Erosion Mechanisms of Fused Cast AZS Blocks: A Result of Synergistic Factors

The erosion of AZS blocks within glass melting furnaces is a combined process involving physical scouring, chemical reactions, and high-temperature penetration. The detachment of erosion products (e.g., zircon, mullite) or unreacted block particles can lead to the formation of "zirconia-based stones" in the glass, adversely affecting glass quality. The primary erosion mechanisms are as follows:

1. Chemical Erosion: The Core Erosion Mechanism

Chemical reactions between the glass melt and the AZS block surface damage the block‘s microstructure, constituting the primary cause of erosion. This can be categorized into three main types:

SiO₂ Dissolution and Mullite Decomposition: The matrix phase of AZS blocks consists mainly of mullite (3Al₂O₃·2SiO₂) and a glassy phase. Alkali metal oxides (Na₂O, K₂O) present in the glass melt react with the mullite: 3Al₂O₃·2SiO₂ + Na₂O → 2NaAlSiO₄ + 2Al₂O₃. The resulting sodium aluminosilicate dissolves into the glass melt, causing the block‘s matrix phase to be "dissolved and stripped away." This leaves behind isolated ZrO₂ particles (tetragonal and cubic ZrO₂). Once these ZrO₂ particles lose the support of the matrix, they become easily scoured away by the glass melt, potentially forming stones.

ZrO₂ Reaction and Phase Transformation: At high temperatures, ZrO₂ within the blocks can react with SiO₂ from the glass melt to form zircon (ZrSiO₄): ZrO₂ + SiO₂ → ZrSiO₄. Zircon possesses a higher density (approximately 4.6 g/cm³) compared to both AZS blocks (3.6-3.8 g/cm³) and the glass melt (2.5-2.6 g/cm³). Its formation is accompanied by volume shrinkage, which can lead to microcracks on the block surface. Should zircon particles detach and enter the glass melt, they can form "zircon stones." Furthermore, tetragonal ZrO₂ undergoes a martensitic phase transformation (tetragonal to monoclinic) at approximately 1170°C, accompanied by a 3-5% volume expansion. Repeated thermal cycling can exacerbate the propagation of cracks within the blocks due to this transformation.

Erosion by Sulfides and Sulfates: Within the glass melting furnace environment, SO₃ generated from the decomposition of salt cake (Na₂SO₄) or S²⁻ ions formed under reducing conditions can react with Al₂O₃ in the AZS blocks to form compounds such as sodium aluminum sulfate (Na₃Al(SO₄)₃) or aluminum sulfide (Al₂S₃). These reaction products are generally soluble in the glass melt, further accelerating the erosion of the matrix phase. Concurrently, the presence of sulfides can lower the surface tension of the glass melt, promoting its penetration into the blocks.

2. Physical Scouring and Penetration: Auxiliary Factors Accelerating Erosion

Physical Scouring: High-velocity flow of the glass melt, particularly in areas like the refining zone and throat, exerts a "mechanical grinding" effect on the AZS block surfaces. This action scours away the weakened layer formed by chemical erosion or dislodges isolated ZrO₂ particles, continually exposing fresh block surface and thereby enabling ongoing erosion.

High-Temperature Penetration: The viscosity of the glass melt decreases significantly at high temperatures (e.g., approximately 10 poise at 1600°C). This lower viscosity allows the melt to penetrate into the block‘s interior through pores, microcracks, or masonry joints. Once inside, it reacts with the internal matrix phase, forming a distinct "penetration layer." The significant difference in the thermal expansion coefficient between this penetration layer and the original block body often leads to spalling cracks during cooling cycles, accelerating the damage to the block.

3. Interface Erosion Between Refractory Mortar and Blocks: An Easily Overlooked Weak Point

The zirconia-containing refractory mortar used for masonry differs from the AZS blocks in terms of composition and density, and its corrosion resistance is typically inferior. The glass melt tends to preferentially erode the mortar, leading to "joint erosion" – where the mortar joint is scoured out into a groove by the glass melt. This undermines the support for the adjacent blocks, potentially causing them to loosen or crack, and creating a vulnerable "breakthrough point" for further erosion.

The core strategy for protecting fused cast AZS blocks involves reducing chemical attack, minimizing physical scouring, and blocking penetration paths. Implementing a full-lifecycle management approach encompassing "Optimized Selection, Enhanced Construction, Operational Control, and Maintenance Repair" is key to extending their service life and reducing the risk of glass stone defects.

1. Optimized Selection and Block Quality Control: Reducing Erosion Risks at the Source

Precise Grade Matching: The selection of the AZS grade should be based on the specific erosion intensity of each furnace section. For instance, 41# AZS blocks are essential for hot spot areas. For ultra-high-temperature, high-erosion sections like the refining zone, "high-density 41# AZS blocks" (with bulk density ≥ 3.75 g/cm³ and apparent porosity ≤ 2%) are recommended. Their lower porosity hinders glass melt penetration, resulting in superior corrosion resistance.

Strict Block Quality Control: During procurement, the quality of AZS blocks should be verified by testing their microstructure (ensuring uniform ZrO₂ particle distribution and absence of significant defects in the matrix phase), bulk density, apparent porosity, and cold crushing strength. The use of inferior blocks resulting from inadequate melting or casting defects must be avoided.

2. Enhanced Construction Quality: Building the "First Line of Defense" Against Erosion

Optimized Masonry Process: Employ a "staggered joint masonry" pattern to prevent the formation of continuous vertical joints. Strictly control the mortar joint thickness to 1-1.5 mm. The refractory mortar must be mixed uniformly to ensure a tight bond between the blocks and the mortar, thereby reducing penetration through the joints.

Strengthened Interface Treatment: Applying a "roughening treatment" to the block bonding surfaces increases roughness and enhances the bond strength with the refractory mortar. After masonry, applying an overall coating of a zirconia-based surfacing material (1-2 mm thick) to the tank wall surface can help fill surface microcracks and pores, blocking potential paths for glass melt penetration.

Standardized Heating and Baking: A scientifically developed baking curve must be followed. During the low-temperature stage (≤ 200°C), a slow heating rate (5-10°C/h) is critical to remove moisture from the blocks and mortar. In the medium-high temperature stage (200-1000°C), the heating rate can be gradually increased (10-20°C/h) to avoid crack formation caused by thermal stress.

3. Optimized Furnace Operating Parameters: Reducing the Impact of Erosive Media

Stable Temperature Field: Optimize the burner arrangement and precisely control the air-to-fuel ratio to ensure a uniform temperature distribution within the furnace (aiming for transverse temperature differences ≤ 20°C and longitudinal differences ≤ 50°C). Preventing localized overheating, particularly ensuring the refining zone temperature does not exceed 1620°C, helps slow down the rates of chemical reactions.

Glass Melt Flow Rate Control: Based on the furnace‘s production capacity, adjust the throat opening to control the glass melt flow rate at AZS-block-lined sections to within 0.5-1 m/h, thereby reducing physical scouring. In areas prone to severe scouring, such as the throat inlet, installing "buffer blocks" or "flow diverter blocks" can alter the flow direction of the glass melt and lessen the scouring intensity.

Optimized Furnace Atmosphere: Maintain a weakly oxidizing atmosphere inside the furnace (excess air ratio typically between 1.05 and 1.15) to prevent the formation of localized reducing atmospheres. Control the amount of salt cake used (generally not exceeding 2% of the total raw material mass) to minimize the generation of SO₃ and S²⁻, thus reducing sulfide-induced erosion.

4. Daily Maintenance and Repair: Timely Intervention to Block Erosion Propagation

Regular Inspection and Monitoring: Conduct daily visual inspections of the AZS block lining surfaces through observation ports, checking for defects like cracks, spalling, or erosion grooves. Use ultrasonic thickness gauges on a weekly basis to measure the remaining thickness of critical tank walls, focusing on hot spots and the refining zone. A replacement plan should be formulated when the erosion depth reaches one-third of the original block thickness.

Timely Defect Repair: Minor cracks or localized erosion on the block surface should be promptly repaired using specialized "zirconia-based repair materials" (composed of fine fused cast AZS powder and a binder). For grooves formed by the erosion of mortar joints, the "pressing-in method" can be used to fill them with a zirconia-based ramming mixture, blocking further penetration of the glass melt.

Reasonable Cold Repair Scheduling: When the average erosion depth of the AZS blocks reaches 50% of the designed thickness, or if large-area cracking or loosening occurs, the furnace should be shut down in a timely manner for cold repair to replace the damaged blocks. This prevents more serious furnace accidents and batch glass quality issues resulting from potential block collapse.

Fused cast AZS blocks act as the "core protective barrier" of glass melting furnaces. Their erosion is a complex process resulting from the combined effects of chemical, physical, and interfacial factors, directly influencing both furnace service life and glass product quality. Effective protection of AZS blocks necessitates the establishment of a comprehensive, full-lifecycle management system spanning "Selection — Construction — Operation — Maintenance." This involves: matching the appropriate grade to the operating conditions through precise selection; establishing a solid foundation via standardized construction; minimizing erosion through optimized operational practices; and halting the progression of damage through timely maintenance interventions. Ultimately, this integrated approach aims to extend block service life, reduce the incidence of glass stone defects, and maintain control over production costs.

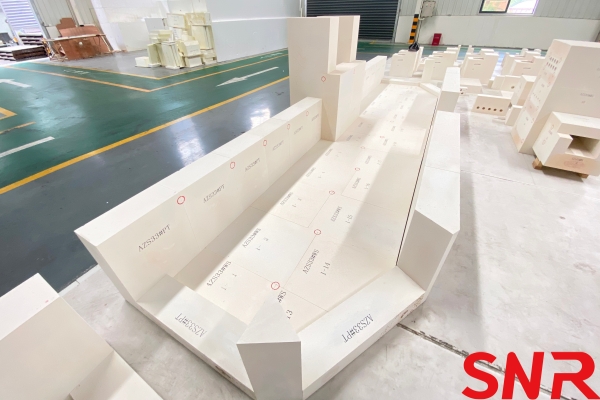

Henan SNR Refractory Co., Ltd. possesses approximately 25 years of specialization in the production of fused cast AZS blocks. We utilize high-quality raw materials and advanced fusion technology to provide customers with superior products. Every stage of our process, from raw material procurement to final product delivery, is subjected to stringent quality inspection, ensuring all performance indicators meet established standards. You can use our products with confidence.

Should you have any requirements, please feel free to contact us at any time.

Should you have any requirements, please feel free to contact us at any time.

Web: www.snr-azs.com

Email: wendy@snrefractory.com