In the glass manufacturing industry, the glass furnace is the core equipment that determines production efficiency, product quality, and corporate profitability. The throat, serving as the critical passage connecting the melting end and the refining end within the glass furnace, directly impacts the entire glass furnace‘s service life and the continuity of glass production. However, the throat area is subjected to harsh operating conditions including high temperatures (above 1500°C), strong corrosion and erosion (from chemical attack and abrasive glass flow), and high stress (thermal shocks and structural loads). Traditional refractory materials often struggle to withstand these conditions, frequently experiencing issues like erosion, spalling, and structural cracking, leading to forced glass furnace shutdowns for maintenance. This not only causes significant economic losses but also severely disrupts production schedules. Against this backdrop, fused cast AZS-41 blocks have become a long-term solution to the frequent failures and short service life in the flow hole area of glass furnaces, thanks to their exceptional high-temperature resistance, corrosion resistance, and erosion resistance.

1. Operational Challenges and Industry Problems in the Glass Furnace Throat Area

The throat is the key channel through which molten glass flows from the melting end to the refining end. Its cross-section is typically rectangular or circular, with a narrow internal space that serves the dual functions of transportation and initial refining. During operation, this area faces three core challenges:

First, extreme high-temperature environment. The throat area is in direct contact with molten glass at 1550 - 1600°C, and the glass flow rate within the channel is relatively fast (typically 0.5 - 1.2 m/h). Refractory materials must continuously endure high-temperature exposure; insufficient refractoriness can easily lead to softening and deformation. Second, strong chemical corrosion. Molten glass contains a large amount of alkaline oxides such as Na₂O and K₂O, which react with components like Al₂O₃ and SiO₂ in the refractory materials, forming low-melting-point compounds (e.g., albite, orthoclase), causing the refractory surface to layer and spall. Finally, there is physical erosion and thermal shock. The high-speed flow of molten glass causes continuous physical erosion on the surface of the refractory material. Meanwhile, temperature fluctuations during glass furnace heating, cooling, and production processes (with temperature differences reaching 200 - 300°C) can cause thermal expansion and contraction of the refractory material. If the thermal shock stability is poor, cracks are highly likely to occur, further exacerbating the penetration and erosion of the molten glass.

According to industry statistics, the average service life of throat areas using traditional high-alumina blocks or ordinary fused cast AZS-33/36 blocks is only 3 - 5 years, and in some high-load photovoltaic glass furnaces, it can be less than 2 years. Each shutdown for maintenance requires replacing all throat refractories, incurring material costs of 200,000 - 300,000 RMB and a production stoppage of 7 - 10 days, leading to direct economic losses (including production loss) exceeding one million RMB. Therefore, finding a refractory material that can adapt to the harsh conditions of the throat area and extend its service life has become an urgent need for glass manufacturers to reduce costs and enhance competitiveness.

2. Technical Basis of Fused Cast AZS Refractory blocks: Core Logic from Composition to Performance

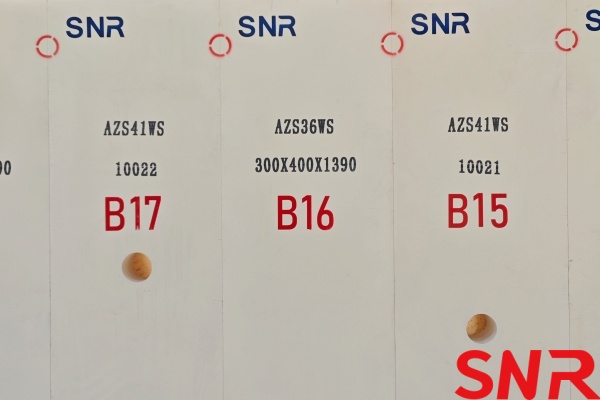

To understand the advantages of fused cast AZS-41 blocks, it‘s essential to grasp the technical essence of fused cast AZS refractories. AZS is the abbreviation for Al₂O₃ (Alumina), ZrO₂ (Zirconia), and SiO₂ (Silica). The core technology lies in precisely optimizing refractory properties by adjusting the proportions of these three components. Based on ZrO₂ content, fused cast AZS blocks can be categorized into models like AZS-33 (33% ZrO₂), AZS-36 (36% ZrO₂), and AZS-41 (41% ZrO₂). The ZrO₂ content directly determines the block‘s corrosion resistance and high-temperature performance – ZrO₂ has a high melting point of 2715°C and strong chemical stability, effectively resisting erosion by molten glass. Thus, higher ZrO₂ content results in better performance under severe conditions.

Compared to traditional fireclay blocks and high-alumina blocks, fused cast AZS blocks are produced using a high-temperature melting + centrifugal casting process: Raw materials like alumina, zirconia, and silica sand are mixed in proportion, melted into a homogeneous glassy liquid in an electric arc furnace at 1800 - 2000°C, then the liquid is poured into molds via centrifugal force, forming a dense block body after slow cooling and annealing. This process gives fused cast AZS blocks two core advantages: firstly, extremely low porosity (bulk density ≥3.6 g/cm³, apparent porosity ≤3%), much lower than ordinary refractory blocks (porosity 15% - 20%), effectively preventing molten glass penetration; secondly, uniform micro-structure, with no significant grain boundary defects inside the block, avoiding the problem of localized accelerated erosion due to structural in-homogeneity found in traditional refractories.

Among the various models, AZS-33/36 blocks, due to their lower cost, are widely used in relatively mild areas of the glass furnace like sidewalls and bottom paving. In contrast, AZS-41 blocks, with their higher ZrO₂ content and denser structure, have become the dedicated refractory material for critical zones like the throat and doghouse, where their performance advantages are fully utilized, especially in the throat area.

3. Core Performance of Fused Cast AZS-41 blocks: Precisely Matching Throat Area Requirements

The reason fused cast AZS-41 blocks can serve as a long-term solution for the throat area lies in their high compatibility with the operational demands of this zone. From high-temperature resistance, corrosion resistance, and erosion resistance to thermal shock stability, each performance characteristic specifically addresses a core challenge in this area.

(1) Ultra-High Temperature Resistance: Withstanding Extreme Heat Without Softening

The glass temperature in the throat area remains stable above 1550°C, and the flame temperature at the glass furnace crown can reach 1700°C. Traditional refractory materials are prone to load softening (deformation under pressure) at these temperatures. In contrast, the refractoriness under load (RUL at 0.2MPa) of fused cast AZS-41 blocks is as high as 1650°C or more, far exceeding the actual working temperature of the throat. Even under long-term high-temperature conditions, it maintains a stable structural form without softening, deformation, or risk of collapse. Furthermore, its pyrometric cone equivalent (PCE) (resistance to melting) can reach 1850°C, fully meeting the maximum temperature requirements of glass furnaces, providing a fundamental guarantee for the long-term stable operation of the throat area.

(2) Superior Corrosion Resistance: Preventing Glass Erosion and Spalling

Alkaline oxides (like Na₂O) in molten glass are the primary challenge for throat refractories. Al₂O₃ in traditional high-alumina blocks reacts with Na₂O to form NaAlSiO₄ (albite), which has a melting point of only about 1100°C. At high temperatures, this forms a molten corrosion layer that gradually spalls off with the glass flow, causing continuous thinning of the refractory block. However, fused cast AZS-41 blocks, with a ZrO₂ content as high as 41%, exhibit very low reactivity between ZrO₂ and Na₂O, resulting in almost no chemical reaction, effectively resisting erosion by alkaline oxides. Simultaneously, their dense structure prevents glass liquid from penetrating the block interior, avoiding structural loosening caused by internal erosion. Inspection data from a photovoltaic glass company showed that the annual erosion rate in the throat area using fused cast AZS-41 blocks was only 0.5 - 1 mm, significantly lower than the 2 - 3 mm for traditional AZS-36 blocks, directly extending service life by over 50%.

(3) Excellent Erosion Resistance: Withstanding High-Speed Glass Flow Without Wear

The glass flow velocity in the throat can reach 0.8 - 1.2 m/h. The glass flow velocity in the throat can reach 0.8 - 1.2 m/h. The high-speed flowing glass causes continuous physical scour on the refractory surface, particularly at the corners of the throat inlet and outlet, where the scour intensity is higher. Traditional refractory blocks often fail prematurely due to excessive surface wear. Fused cast AZS-41 blocks, with their high density (bulk density 3.65 - 3.75 g/cm³) and high hardness (Mohs hardness ≥8), exhibit excellent erosion resistance. Scanning Electron Microscope (SEM) observations reveal that after long-term scour, the AZS-41 block surface only shows slight polishing marks, without significant grooves or depressions, whereas ordinary AZS-36 block surfaces develop scour grooves 2 - 3 mm deep. This erosion resistance ensures the throat channel‘s cross-section remains stable over time, preventing abnormal glass flow velocities due to refractory wear, which could affect glass quality.

(4) Stable Thermal Shock Resistance: Resisting Cracking Under Temperature Fluctuations

During glass furnace startup and shutdown, temperature changes in the throat area can reach 300°C/h. Even during normal operation, temperature fluctuations of 100 - 200°C can occur due to adjustments in glass flow rate, fuel variations, etc. Traditional refractory blocks, due to uneven thermal expansion coefficients, are prone to cracking under sudden temperature changes. Once cracks form, molten glass rapidly penetrates, accelerating block deterioration. By optimizing the ratio of Al₂O₃ to ZrO₂, the fused AZS-41 block achieves a thermal expansion coefficient of 5.5×10⁻⁶/℃ (20-1000℃), with a smooth expansion curve and no significant abrupt changes.. Laboratory tests show that AZS-41 blocks subjected to cyclic thermal shock tests from 1100°C to room temperature remained crack-free and without spalling after 50 cycles, whereas ordinary AZS-36 blocks showed visible cracks after 30 cycles. This excellent thermal shock stability ensures the throat area maintains structural integrity during both glass furnace startup/shutdown and normal operation.

4. Practical Application Cases of Fused Cast AZS-41 blocks: Demonstrating Long-Term Value Through Data

The advantages in theoretical performance must ultimately be validated through practical application. In recent years, fused cast AZS-41 blocks have been widely used in the throat areas of glass furnaces across various sectors, including photovoltaic glass, electronic glass, and container glass, with their longevity and cost-effectiveness receiving full market recognition.

Case 1: Throat Renovation in a 500t/d Glass Furnace at a Photovoltaic Glass Company

This company previously used traditional high-alumina blocks for the throat refractory, with an average service life of only 18 months. Each shutdown for replacement cost 250,000 RMB in materials, 80,000 RMB in labor, and a 7-day production stoppage resulting in a production loss (based on 500t/d, PV glass average price 2000 RMB/t) of 7 million RMB, totaling over 7.33 million RMB in comprehensive losses. In 2022, the company replaced the entire throat area with fused cast AZS-41 blocks, employing specialized masonry techniques provided by the manufacturer (staggered joints, mortar joints controlled at 1 - 2 mm, using high-temperature binders). As of June 2024, this throat has been operating stably for 28 months. Professional inspection showed an average erosion of only 1.2 mm in the refractory blocks, with remaining thickness sufficient for at least 12 more months of operation. The total service life is projected to exceed 40 months. Calculating solely from the extended lifespan perspective, the company can avoid one shutdown for maintenance, directly saving 7.33 million RMB in comprehensive losses. Although the material cost of AZS-41 blocks was 120,000 RMB higher than AZS-36 blocks, the input-output ratio reached 1:61, demonstrating significant economic benefits.

Case 2: Throat Optimization in a 200t/d Glass Furnace at an Electronic Glass Company

Electronic glass requires extremely high purity and flatness. Erosion and spalling of throat refractories can introduce impurities into the glass melt, increasing the defect rate. This company previously used ordinary high-alumina blocks, resulting in a throat life of only 12 months and a defect rate as high as 3.5% for electronic glass due to refractory erosion. In 2023, the company renovated the throat using fused cast AZS-41 blocks, coupled with the manufacturer‘s preheating + gradient heating installation process (to prevent cracking from sudden temperature changes). After the renovation, the throat operated for 15 months without any erosion or spalling. The impurity content in the glass melt decreased from 0.08% to 0.03%, and the defect rate dropped to 1.2%. Based on a 200t/d capacity and a 2.3% reduction in defect rate, the company can reduce monthly losses from defects (electronic glass average price 8000 RMB/t) by 36,800 RMB, leading to an annual income increase of 441,600 RMB, far exceeding the additional cost of AZS-41 blocks. Simultaneously, the throat life is expected to extend to 36 months, further reducing maintenance frequency and costs.

5. Market Value and Cost-Benefit of Fused Cast AZS-41 blocks: The Economic Logic Behind Longevity

In today‘s increasingly competitive glass industry, companies focus not only on the initial cost of refractories but also on their total cost of ownership over the entire life-cycle. Although fused cast AZS-41 blocks have a higher initial price than traditional refractory materials, their cost advantage becomes extremely evident when analyzing the total life-cycle cost, including initial cost + maintenance cost + shutdown losses.

The table below clearly illustrates the significant advantages of AZS-41 over AZS-33 specifically in the throat application:

|

Performance Indicator |

AZS-33 block |

AZS-41 block |

Impact on Throat Service Life |

|

Zirconia (ZrO₂) Content |

33% ± 1% |

41% ± 1% |

Directly determines the upper limit of corrosion resistance |

|

Apparent Porosity |

≤ 1.5% |

≤ 1.0% |

Lower porosity means fewer channels for corrosive media penetration. |

|

Glass Phase Exudation Temperature |

Approx 1150°C |

Approx 1250°C |

Higher exudation temperature indicates greater structural stability under throat conditions |

|

Glass Corrosion Index (Static Test, 1500°C, 48h) |

Baseline 20%-30% |

lower than AZS-33 |

Lower corrosion index means slower block wear, longer life |

|

Expected Service Life |

5-7 years (requires more frequent monitoring) |

8-12 years (or even longer) |

Directly extends glass furnace cold repair cycle, significantly reduces average annual maintenance cost. |

Thus, although the initial procurement cost of AZS-41 is higher than AZS-33, its life-extending effect in the throat results in a Total Cost of Ownership (TCO) over the glass furnace‘s life-cycle that is much lower than the latter, making it a more economical choice for achieving long-term operation. Furthermore, with the capacity expansion of high-end glass products like photovoltaic glass and electronic glass, glass furnace sizes are continuously increasing (from 300t/d to 1000t/d), leading to larger throat dimensions and higher loads, which demand higher performance from refractory materials. The longevity of fused cast AZS-41 blocks not only meets the operational needs of large glass furnaces but also reduces the risk of full glass furnace shutdowns due to throat failures, ensuring stable production for companies. Additionally, their excellent corrosion resistance minimizes the introduction of refractory impurities into the glass melt, improving product quality and helping companies establish a competitive edge in the high-end glass market.

6. Conclusion: Choosing Fused Cast AZS-41 blocks to Safeguard the Throat Area of Glass Furnaces

The stable operation of the throat area in glass furnaces is crucial for glass manufacturers to achieve efficient, low-cost, and high-quality production. Fused cast AZS-41 blocks, with their ultra-high temperature resistance, corrosion resistance, scour resistance, and stable thermal shock stability, precisely address the operational challenges of the throat area. Based on practical application cases, their service life can reach 1.8 - 2 times that of traditional refractory materials, effectively reducing the frequency of shutdowns for maintenance and lowering comprehensive costs.

Under the current trend of the glass industry moving towards high-end and large-scale development, choosing fused cast AZS-41 blocks as the refractory material for the throat area is not only a long-term investment in glass furnace equipment but also a crucial measure for companies to enhance production stability, reduce operational risks, and strengthen market competitiveness. We are committed to providing high-quality fused cast AZS-41 block products, professional installation guidance, and comprehensive after-sales service to ensure long-term protection for the throat area of every customer‘s glass furnace, working hand-in-hand with enterprises to achieve sustainable development.

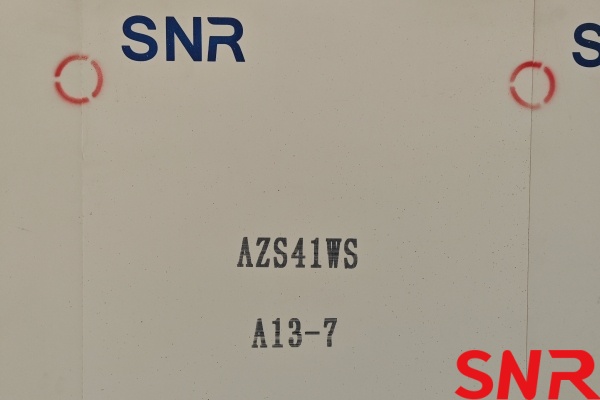

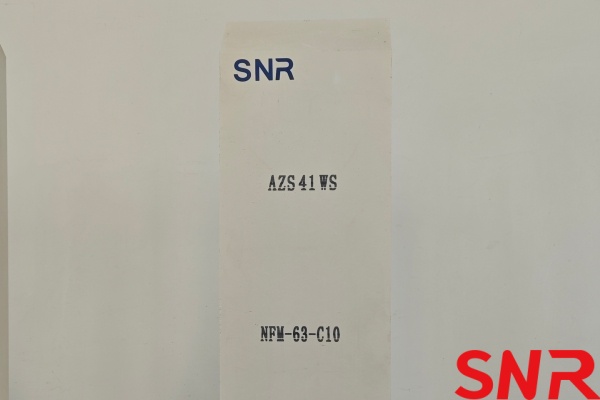

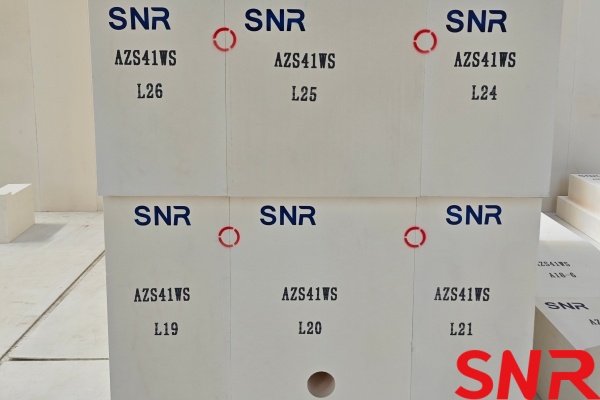

Henan SNR Refractory Co., Ltd. is dedicated to the manufacture, research and development of fused cast AZS refractory blocks and bonded refractory materials for the glass industry. Meanwhile, SNR can provide total solutions and services for glass furnace design, glass furnace construction, renovation, and upgrading. Please contact me if you have any requirements.

zoe@snrefractory.com/ WhatsApp:+86 15670323812