In the heart of a glass plant, a massive glass furnace operates relentlessly day and night, with the molten material inside glowing with intense heat reaching 1600°C. Deep within the "chest" of this thermal equipment, a group of unsung heroes called "tuckstones" silently support the tens-of-tons-heavy crown structure. These seemingly ordinary refractory materials are, in fact, the lifeline maintaining the entire furnace‘s safety. If these "bones" fail, it could lead to production interruptions at best, or a complete furnace collapse at worst, causing economic losses amounting to tens of millions.

In the modern glass industry, the importance of tuckstones is often underestimated. Statistics show that furnace shutdown accidents caused by tuckstone damage account for over 35% of all furnace accidents. This data sufficiently illustrates how crucial these refractory components, hidden within the steel structure, are to the stable operation of the entire production system.

I. The Invisible Battleground: The Extreme Working Environment of Tuckstones

II. The Invisible Enemy: Multiple Erosion Mechanisms of Tuckstones

III. Comprehensive Protection: Building a Systematic Protection System

IV. Deep Optimization for Special Application Scenarios

V. Economic Benefits and Sustainable Development

Ⅵ. Conclusion: Towards Continuous Intelligent Guardianship

I. The Invisible Battleground: The Extreme Working Environment of Tuckstones

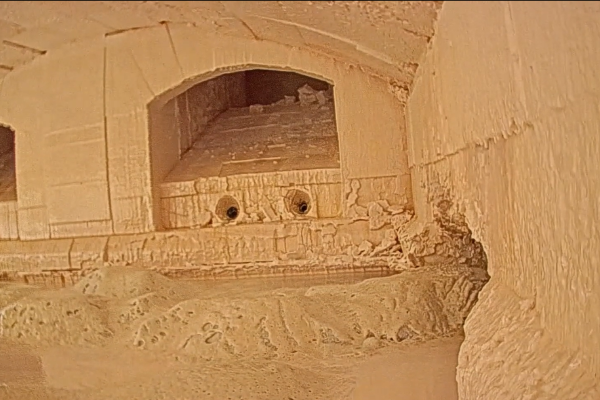

The service environment of tuckstones can be described as extremely harsh. They must not only endure continuous high-temperature exposure but also cope with complex mechanical stresses. In a typical float glass furnace, a single tuckstone can bear a pressure of 5-8 tons, equivalent to the weight of a small car. More severely, during the furnace heat-up process, expansion of the crown material generates additional horizontal thrust on the tuckstones. This complex stress state keeps the material operating at its limits for extended periods.

From a thermal engineering perspective, the location of tuckstones is a typical thermodynamic sensitive zone.This area lies precisely within the condensation zone for alkali metal oxide vapors. When the temperature gradient distribution within the furnace is improper, volatile alkali components tend to concentrate here. Research indicates that when the temperature in the breast wall area of the furnace falls below 1300°C, the condensation efficiency of alkali vapor increases significantly, creating hidden dangers for subsequent chemical attack.

It is worth noting that different types of glass furnaces have varying requirements for tuckstones. In electronic glass furnaces, due to the extremely high purity requirements of the production process, tuckstones also need low-pollution characteristics; whereas in container glass furnaces, alkali erosion resistance becomes the primary consideration. This differentiated demand drives tuckstone materials towards specialized, customized development.

II. The Invisible Enemy: Multiple Erosion Mechanisms of Tuckstones

1. Chemical Erosion: The Fatal Attack of Alkali Vapors

Chemical erosion is the most significant threat faced by tuckstones. This process begins with the volatilization of alkali metal oxides from the batch materials. At high temperatures of 1500°C, the volatilization rate of Na₂O and K₂O increases exponentially. These volatile alkali components rise with the hot gas flow and begin their destructive journey when they encounter the relatively cooler crown area.

When alkali vapors condense on the tuckstone surface, an intense chemical reaction unfolds. The liquid alkali reacts with components in the brick, such as Al₂O₃ and SiO₂, forming new minerals like nepheline or leucite. This process is accompanied by significant volume expansion, with expansion rates reaching 15%-20%. At the microscopic level, this volume change generates numerous microcracks within the material, making the originally dense brick structure porous and fragile.

More worryingly, this chemical erosion is self-accelerating. As erosion progresses, the thermal conductivity of the brick changes, causing the surface temperature to decrease further, which in turn promotes more alkali vapor condensation, creating a vicious cycle. Field measurement data shows that without effective protective measures, the erosion rate of tuckstones can reach 2-3 millimeters per month.

2. Physical and Thermal Erosion: Continuous Structural Challenges

Thermal stress damage is another major challenge for tuckstones. During furnace start-ups and shutdowns, the rate of temperature change often reaches 50-100°C per hour. Such drastic temperature fluctuations generate significant thermal stress within the brick. Finite element analysis shows that under typical temperature field distributions, the thermal stress inside tuckstones can reach 10-15 MPa, a value already approaching the tensile strength limit of some refractory materials.

The impact of mechanical stress should not be overlooked either. In addition to bearing continuous static loads, tuckstones must also handle dynamic loads caused by furnace vibrations. These alternating stresses couple with thermal stresses, accelerating material fatigue damage. Particularly near the furnace doghouse, where mechanical vibration is more pronounced, the damage rate of tuckstones is often 30% higher than in other areas.

High-temperature creep is another often overlooked damage mechanism. Under long-term high-temperature conditions, refractory materials undergo slow plastic deformation. Experimental data indicates that at an operating temperature of 1350°C, the annual creep of fused cast AZS block tuckstones can reach 0.5%-1.0% of the initial dimension. This seemingly minor deformation alters the stress distribution within the structure, thereby affecting the stability of the entire support system.

III. Comprehensive Protection: Building a Systematic Protection System

1. Material Innovation: Building the First Line of Defense

Material selection is the foundation of tuckstone protection. Current mainstream solutions have formed a complete technical system:

The Fused cast AZS block series is the preferred choice due to its excellent overall performance. Among them, the 33# product is suitable for working environments below 1400°C, 36# can be used for medium-load conditions up to 1500°C, and 41# is specifically designed for extreme conditions above 1550°C. These materials, through special casting processes, form a microstructure primarily composed of corundum and zirconia-corundum phases, giving them outstanding erosion resistance. Measured data shows that the alkali erosion resistance of high-quality fused cast AZS block is 3-5 times that of traditional silica bricks.

Alumina-based materials show unique advantages in high-end applications. Among them, α-β alumina bricks, due to their almost zero glass phase content, are particularly suitable for electronic and optical glass furnaces with strict glass quality requirements. β alumina bricks, leveraging their unique platelet crystal structure, perform exceptionally well in thermal shock resistance.

In recent years, the development of new composite materials has made breakthrough progress. For example, materials developed by introducing chromium-zirconium composite oxides have successfully elevated thermal shock resistance to levels withstanding over 20 air-quenching cycles from 950°C. These materials utilize special particle size distributions and microporous structure designs, ensuring both material strength and improved penetration resistance.

2. Structural Optimization: Eliminating Hidden Dangers at the Root

Insulation system design has proven to be the most effective protective measure in practice. By establishing accurate thermal models, the insulation layer thickness and structure can be optimized. In practical applications, good insulation design can increase the tuckstone area temperature by 150-200°C, thereby reducing the probability of alkali vapor condensation by over 70%. This not only significantly extends the service life of tuckstones but also brings 5%-8% fuel savings.

The design of the Expansion control system needs to be based on precise thermodynamic calculations. Taking fused cast AZS block as an example, its thermal expansion coefficient at 1000°C is about 0.8%. This means a 10-meter-long crown will expand by 80 mm during heat-up. Scientific expansion joint design must fully absorb this deformation while ensuring sealing performance.

Steel structure optimization is a systematic project. Modern furnaces typically use finite element analysis to optimize steel structure design, ensuring sufficient stiffness and strength. Furthermore, the introduction of intelligent monitoring systems makes real-time adjustment of tie rod tension possible, providing technical assurance for maintaining the optimal stress state.

3. Process Control: Refined Management Practices

Temperature stability control is key to extending tuckstone life. Advanced control systems can keep furnace temperature fluctuations within ±3°C and pressure fluctuations within ±1 Pa. This precise control not only reduces thermal stress impact but also decreases alkali volatilization by 20%-30%.

Optimization of raw material formulation needs to start at the source. By using granular raw materials and optimizing batch granularity distribution, carryover can be reduced by over 40%. Meanwhile, appropriately adjusting the content of alkali metal oxides, without compromising glass quality, can also significantly reduce erosion of tuckstones.

4. Intelligent Maintenance: Predictive Protection Strategy

Modern glass furnaces are evolving towards intelligent maintenance. Through sensor networks installed at key locations, the following parameters of tuckstones can be monitored in real-time:

►Temperature field distribution and its trends

►Structural stress state

►Material thickness changes

►Surface erosion condition

This data, processed by cloud algorithms, can predict maintenance needs 4-6 weeks in advance, providing a scientific basis for planned repairs. Furthermore, the application of advanced detection technologies like laser thickness measurement and infrared thermography has significantly improved maintenance accuracy.

In terms of repair techniques, hot replacement processes have become quite mature. Using specialized robotic systems, tuckstone replacement can be completed without affecting production, with positioning accuracy of the entire process reaching ±1 mm. The application of hot spraying repair technology enables precise repair of local damage, with a bond strength of the repair layer exceeding 5 MPa.

In different glass production processes, tuckstone protection strategies need to be tailored:

The particularity of Ultra-clear glass furnaces lies in their higher thermal conductivity. The bottom temperature of such furnaces is usually 100-150°C higher than ordinary furnaces, leading to increased glass flow velocity and consequently intensified convective erosion. For this situation, improved fused cast AZS block materials, by adding rare earth elements, optimize the material‘s erosion resistance and thermal stability. Measured data shows that the service life of such materials in ultra-clear glass furnaces is extended by over 40% compared to traditional materials.

Protection of special areas requires targeted measures. For example, in the burner port area, as it is directly impacted by flames, the tuckstones there need excellent erosion resistance. Chrome-zirconia mullite materials demonstrate unique advantages in this field due to their specific microstructure. Their spalling resistance is over 50% higher than ordinary materials, fully meeting the usage requirements of this special area.

V. Economic Benefits and Sustainable Development

The economic benefits brought by a scientific tuckstone protection system are significant. Taking a float glass furnace with a daily melting capacity of 600 tons as an example:

►Fuel savings from optimized insulation design can reduce energy expenditure by over 1 million yuan per year

►Preventive maintenance avoiding unplanned shutdowns can reduce economic losses by about 500,000 yuan per incident

In terms of sustainable development, advanced protection strategies also show clear advantages:

Material consumption reduced by over 30%

Material consumption reduced by over 30% Waste generation reduced by 50%

Waste generation reduced by 50% Whole-life carbon emissions reduced by 25%

Whole-life carbon emissions reduced by 25%These data fully demonstrate that the scientific protection of tuckstones holds not only technical value but also enormous economic and environmental benefits.

With the rapid development of new material technologies and digital technologies, tuckstone protection is entering a new stage. In the future, we will see more intelligent protection systems possessing capabilities of self-sensing, self-diagnosis, and self-adjustment. Through the application of digital twin technology, we can simulate and optimize protection strategies in virtual space, achieving more precise and efficient management.

Every successful protection of tuckstones is an enhancement of the glass manufacturing process. This "skeleton" hidden inside the furnace, although invisible, carries the heavy responsibility of the development of the entire glass industry. Its health status not only relates to production safety and stability but is also an important indicator measuring a company‘s technical level and management capability.

In the foreseeable future, with the continuous emergence of new materials and the deep application of intelligent technology, tuckstone protection will inevitably reach a higher level. This invisible battle of guardianship will continue silently within the furnace‘s "chest," providing a solid guarantee for the sustainable development of the glass industry, witnessing the innovation and breakthroughs of this ancient industry in the new era.

Henan SNR Refractory Co., Ltd. has been specializing in the production of fused cast AZS blocks for about 25 years. We use high-quality raw materials and advanced fusion technology to provide customers with high-quality products. From raw material procurement to finished product delivery, every step is strictly quality inspected to ensure that every indicator meets the standards, so you can use it with confidence.

If you have any needs, you can contact me at any time.

If you have any needs, you can contact me at any time.

Web: www.snr-azs.com

Email:wendy@snrefractory.com